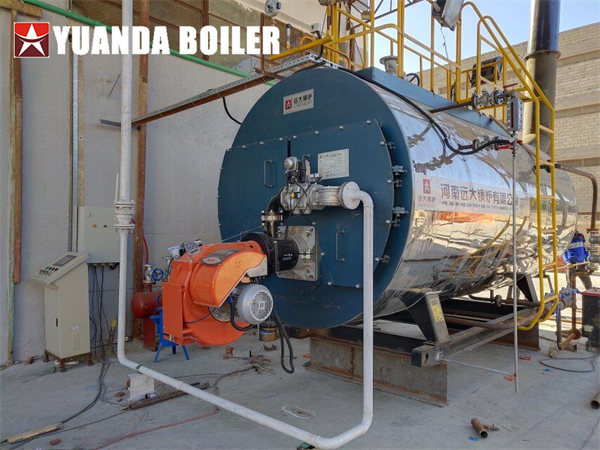

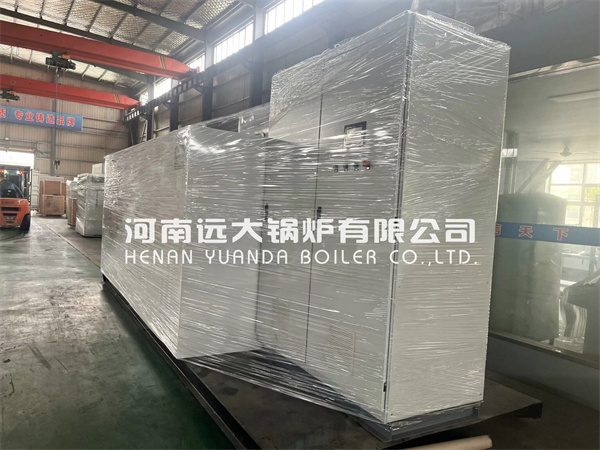

YY (Q) W series thermal oil boiler is a kind of boiler which uses gas(oil) as fuel ,thermic oil as medium, hot oil circulation pump to make the medium to forced circulation, deliver the heat to heating need equipment and then go back to the heating furnace.It can obtain a high operating temperature at low pressure and can do high-precision control on the medium.

1.Quick-setting high strength refractory material,have strong power of solidification and long using cycle.it does not shake off.

2.Integrated and wiring device,more convenience for the wire connection,make overhaul more simply,elegant appearance after installation

3.Double-deck aluminum silicate for heat preservation,the surface temperature of the boiler is no higher than 40℃,energy conservation and efficient

4.Design of angular and smooth surface of outsourcing panel,prevent the injury accident when checking the equipment

5.The outer oil collecting box is designed to prevent the slow rate of grease from carbonizing avoid air leakage

6.Double seal groove design, secondary prevent air leakage design, tight seal, avoid air leakage

7.Unique coil tube repair and integration process, the disk is compact and no gap,there is no smoke short circuit,long gas flow, heated fully, high efficiency

8.Boiler multistage energy saving device design (the tail can set air preheater, wasted heat boiler,economizer),low smoke exhaust temperature, improve boiler efficiency 10%

Advantages

1.Double seal groove design

Secondary prevent air leakage design, tight seal, avoid air leakage

2.Unique tail heating surface design

Boiler rolling chamber wet back structure,small boiler heat loss,avoid overheat caused by over-burning of side panels, and increase thermal efficiency by 2-3%.

3.Unique coil tube repair and integration process

The disk is compact and no gap,there is no smoke short circuit,long gas flow, heated fully, high efficiency

4.Boiler multistage energy saving device design

The tail can set air preheater, wasted heat boiler,economizer,low smoke exhaust temperature, improve boiler efficiency 10%

5.Design of angular and smooth surface of outsourcing panel

Prevent the injury accident when checking the equipment

6.Triple coil,three-pass smoke,fire wrapped in oil structure design,

Large radiant heating furnace,high thermal efficiency of the boiler,prevent the boiler shell from firing deformation at the high temperature

7.Research PCL control board independently,strong compatibility

PLC intelligent touch screen equipment,10-inch touch screen,fool-type operation,safe and reliable,automatic ignition/flame-out/fire switch,high fired gas,low pressure protection,gas leakage protection

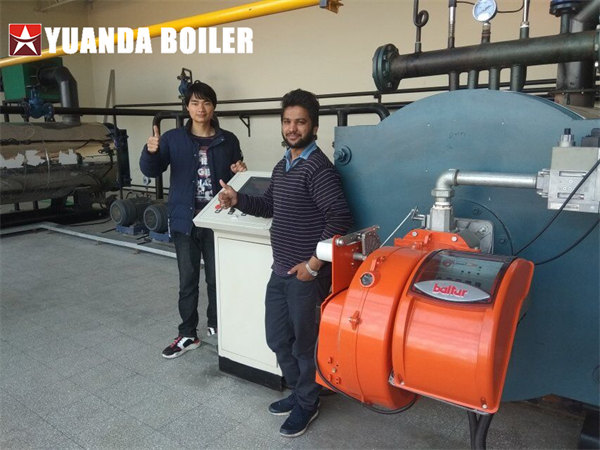

8.Large load imported burner configuration

80% configuration ratio,light load drive,enough thermal energy import,guaranteed output,reduce equipment use fatigue,extend the service life,the quality of inlet valve group is steady and reliable

9.60years’precipitation,mature production technicians team,good matching among the set of equipment,technology skilled,stable quality

10.material supplied by large international factory,manufactured by Anyang Iron Steel and Tianjin Seamless Steel Pipe plant,ensure the quality