Advantages of Economizer (Boiler Economizer)

1. Improve Boiler Thermal Efficiency

-

The economizer uses waste heat from the flue gas to preheat the feed water, increasing the water temperature entering the boiler.

-

This reduces the fuel required for heating and achieves 5%–10% fuel savings.

2. Lower Flue Gas Temperature

-

Effectively reduces the exhaust gas temperature at the boiler outlet, minimizing heat loss.

-

For every 20°C drop in flue gas temperature, boiler efficiency increases by about 1%.

3. Reduce Fuel Consumption and Operating Costs

-

Coal and biomass fuel consumption decreases, resulting in significant cost savings.

-

Especially beneficial for biomass boilers where fuel cost is relatively higher.

4. Improve Boiler Operating Stability

-

Higher and more stable feed water temperature entering the boiler helps maintain stable steam pressure.

-

Reduces thermal stress and prolongs boiler service life.

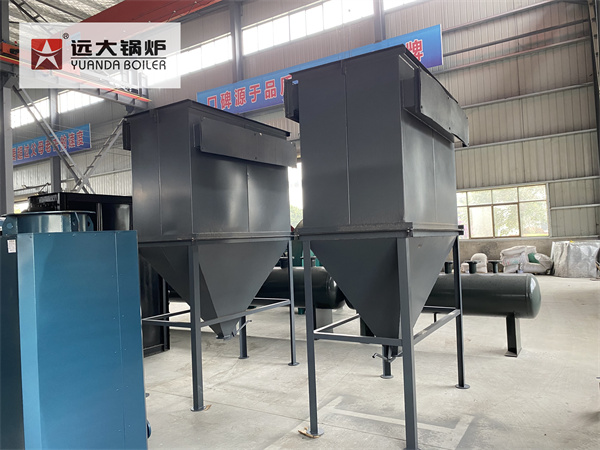

5. Help Reduce Dust Emissions (Indirectly)

-

Lower flue gas temperature improves the efficiency of downstream dust collectors and desulfurization systems.

-

Useful for projects with strict environmental regulations.

6. Enhance System Reliability

-

Reduces heat load on boiler pressure parts and protects heating surfaces.

-

Extends the lifespan of the boiler and tail-heat recovery system.

7. Suitable for Multiple Fuels

-

Applicable to coal, biomass, wood chips, rice husk, palm shell and other solid fuels.

-

Particularly suitable for biomass boilers with high moisture and high volatile content.