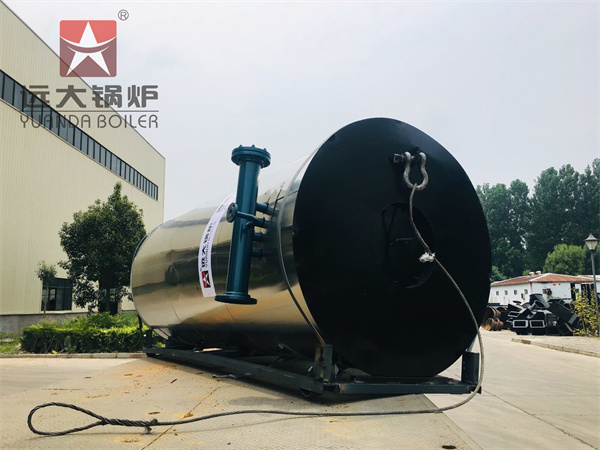

Industrial Helical Coil Thermal Oil Heater Boiler Suppliers

The Industrial Helical Coil Thermal Oil Heater is a highly efficient and reliable heating system designed for industrial applications that require uniform and precise temperature control. Using thermal oil as the heat transfer medium, it provides indirect heating at temperatures up to 200–350°C under low operating pressure. The heater features a helical coil structure, ensuring optimal heat transfer, compact design, and long service life. It is widely used in industries such as chemical, textile, food, plywood, bitumen, and oil processing.

Main Features

-

High Thermal Efficiency

The multi-pass helical coil design ensures maximum heat transfer from the combustion chamber to the thermal oil, achieving an efficiency of up to 90% with optional economizer. -

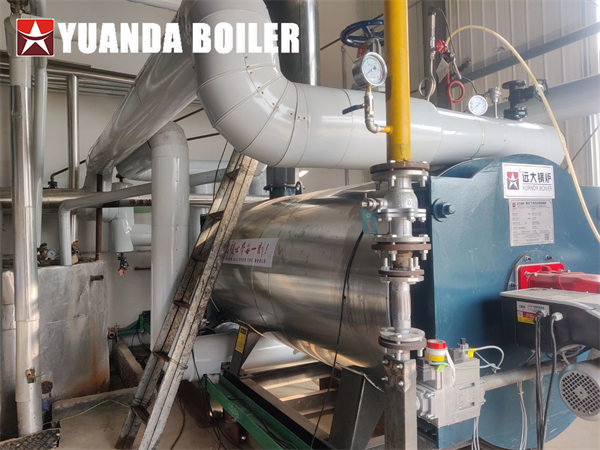

Low Pressure, High Temperature

Provides stable high-temperature heating under low pressure, reducing the risk of explosion and improving safety performance. -

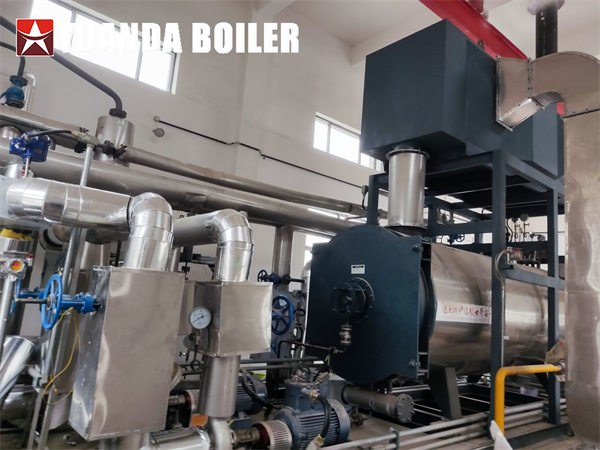

Compact and Modular Design

Space-saving structure with integrated burner, control system, and expansion tank — easy to install and maintain. -

Precise Temperature Control

Equipped with intelligent temperature and flow control systems, ensuring uniform heat distribution and accurate temperature regulation. -

Fuel Flexibility

Available for a wide range of fuels including diesel, natural gas, LPG, heavy oil, coal, biomass, or electricity. -

Reliable Safety System

Includes over-temperature alarm, oil flow switch, pressure protection, and automatic shutdown functions to ensure safe operation. -

Long Service Life

The coil is made of high-quality seamless steel tubes, designed for low thermal stress and corrosion resistance, extending the equipment lifespan.