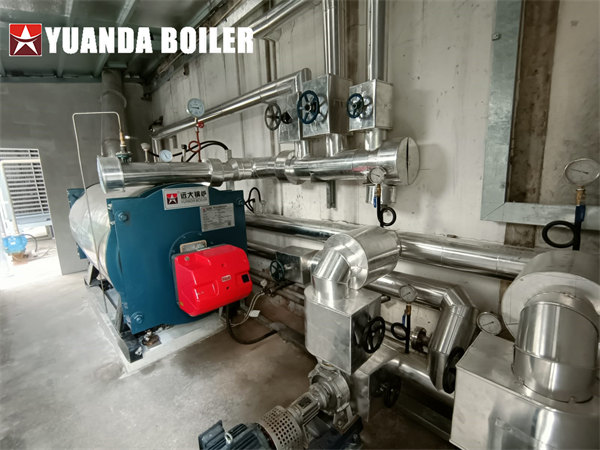

Singapore Food Factory Use 240kw Thermal Oil Boiler With Natural Gas Burner

Thermal oil heater by gas, diesel, lpg.

YYQW horizontal thermal oil heater boiler, high efficiency hot oil heating system.

1.It is easy and convenient to install the boiler,only setting the boiler on the foundation.

2.Heating surface is formed by round coilers, sufficient arrangement, reducing thermal load of tubes surface to ensure safety.

3.Furnace dimensions is matching with the combustion flame,positive pressure combustion,high radiation heat exchange efficiency.

4.Boiler structure is compact,saving the floor area of boiler room.

5.An air pre-heater or heat recovery boiler is placed behind the boiler to improve the thermal efficiency.

Thermal oil heater features

1. Adopted Closed-disc tube design in heating surface, large heating surface, reduce the thermal load on tube surface . The thermal efficiency is high and run safer.

2. The fuel combust adiabatically in the combustion chamber, making it easier to fire and burn more fully, improving boiler thermal efficiency.

3, The media flow is reasonable, thermal conductive oil run from the low import to high export, gas generated during the operation can be remove easily.

4. The top of the furnace is arranged with dense coiled tubing to better protect the top of the furnace, avoid burning furnace roof..

5. Easy installation, no foundation, only according to the upper body and the lower grate can be closed, the installation cycle is short.

Thermal oil heater application

1.Chemical Industry –polymerization industry, oil industry, reaction tank, distillation, enrichment

2.Plastic industry —plastic and squeeze to finalize the design

3.Textile industry — resin stenters, dyeing machine and the dry room, high temperature machine, roller.

4. Rubber industry – rubber vulcanization heating

5. Food industry — cooking dry, vegetable oil refining

6. Wood industry — heating to finalize the design of chipboard sandwich plate, warm up board, fiber

7. Paper industry-multi-layer cardboard of packed carton box, dying and desiccation

8. Others-heating of metal electroplating slot, coating condensation, drying, distillation of pharmaceutical industry, reduction, concentration, dehydration, airconditioning industry, etc.

Thermal oil heater boiler advantages

1. It is convenient to be adjusted, and can supply balanced heat to satisfy the hard work required to precise temperature.

2. Less heat loss, high Thermal Efficiency.

3. Excellent Structure, advanced techniques.

4. Simple operation, serious control.