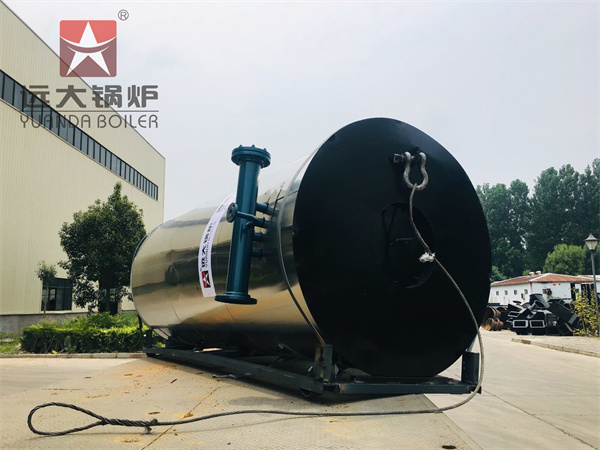

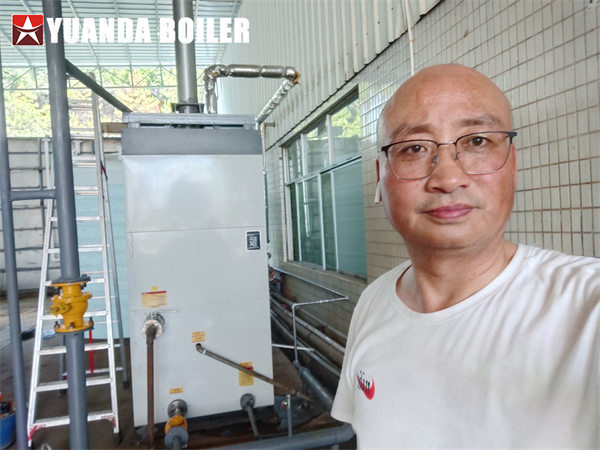

Home » Case » Beverage Food Industry » LHS 300kg Gas Steam Boiler For Chicken Processing Factory In Burundi

LHS 300kg Gas Steam Boiler For Chicken Processing Factory In Burundi

Enhance the efficiency of your chicken processing factory in Burundi with the LHS 300kg Gas Steam Boiler. Designed to meet the unique demands of poultry processing, this high-performance boiler delivers reliable and consistent steam supply. With its gas-powered operation, it ensures cost-effectiveness and reduced environmental impact. The compact design and robust construction make it ideal for limited space installations. Trust the LHS 300kg Gas Steam Boiler to optimize your chicken processing operations, improving productivity and ensuring the highest quality output.

Contact US

Get Price

Share:

Content

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible

More Beverage Food Industry