.jpg)

Biomass Hot Water Boiler

- Capacity:100kw-35000kw; 200,000kcal-24,000,000kcal

- Heating Temperature:0°C-400°C

- Pressure:0.1Mpa-3.8Mpa

- Fuel:Biomass, wood, coal, ricehusk, pellets, shells, straw, bagasse, etc

- Kinds of Boilers:Biomass hot water boiler, biomass thermal oil boiler, biomass steam boiler

Biomass Hot Water Boiler

Heat Capacity: 200kw to 35000kw

Available Fuel: biomass waste, wood waste, ricehusk, coconuts, palm shells, biomass pellets, woochips, etc

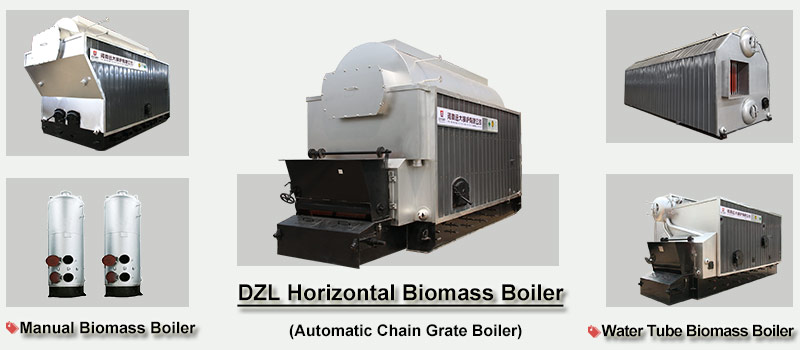

Popular Model DZL biomass boiler

DZ series biomass hot water boiler, including DZL biomass chain grate boiler, DZH biomass travelling grate boiler, DZW biomass reciprocating grate boiler.

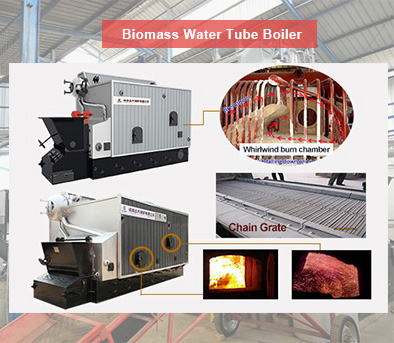

DZ series boiler, is horizontal three-pass water & fire tube boilers with grate combustion device. Threaded pyrotechnic tubes are arranged in the drum to form a convection heating surface, while the drum and the water walls on both sides from a radiation heating surface in the furnace.

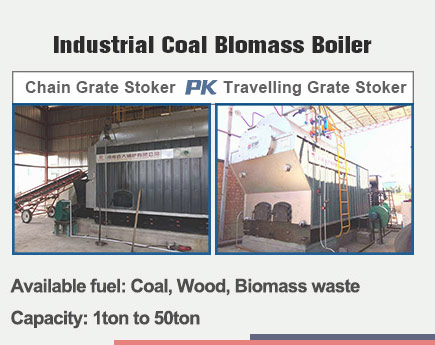

Compare Automatic & Manual Type Boilers

① DZL package boilers are horizontal three-pass water & fire tube boilers with a chain grate stoker structure. Threaded pyrotechnic tubes are arranged in the drum to form a convection heating surface,while the drum and the water walls on both sides from a radiation heating surface in the furnace.

② DZH manual feed boiler, biomass fired boiler with travelling grate, it's the single drum type horizontal three return boilers with fire tubes and water tubes, radiation heat surface in furnace water wall and stove sides. convection heating surface in furnace flanks and threaded tube.

Features Design Advantages

1. Smoke and dust separator chamber

Separate smoke and dust according to inertia,reduce the original effluent concentration of soot.

2. Optimized design CAD

Choose the best furnace from dozens of options,improve economical efficiency.

3. Convex tube plate

1) Improve tube plate flexibility, so as to reduce the heating stress of welded sew at the pipe end.

2) Prevent tube plate cracking, cancel bracing,simplify the structure.

4. Large size of simple circulation loop drop pipe and lower set box

Increase the flow rate of water on water cooling wall in order to prevent subcooled boiling. To prevent pipe explosion,Increase the reliability of water cycle

5. New pattern of furnace arch

Strengthen the combustion, could burn kinds of fuel: wood, coal and biomass, improve combustion efficiency.

Projects Worldwide Service

Recommend: Boiler Accessories

Our Boiler Strict Quality Control

1. Strength calculation report with applied materials information.

2. Hydraulic test report: ensure the standard working pressure and safety.

3. 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod.

4. 100% X-ray inspection report (welding seam): to ensure the quality of the entire boiler.

5. Third-party inspection report: by Zhoukou Institute of Special Equipment Inspection & Technical Research.

Why Choose Us ?

1. We offer all kinds of boiler machine, customized service for customers' demand, send your specific details to us.

2. 60+Years' experience in boiler design, technique, production, installation and operation. 10+Years export boiler experience.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, Yuanda boilers have been exported to 88 countries and regions such as Bangladesh, Nigeria, Chile, Russia, etc. More than 8000+ boiler projects worldwide.

Service After-sale Service

1. Full-life After-sale Service

2. Onsite Operation Training Service

3. Online Monitoring System

4. Engineer Abroad Installation and Commissioning Service

5. Training Service Content:

-Boiler basic knowledge

-Boiler structure introduction on site

-Boiler control theory

-Boiler burner theory and adjusting method

-Boiler water treatment introduction and water quality test method

-Boiler operation training

-Boiler room system introduction

-Boiler debugging introduction

-Introduction of Boiler faults, reason and solution

-Field simulation solves all kinds of common failures

-Boiler maintenance introduction

| DZ Series Hot Water Boiler Technical Parameter Table | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Rated capacity(MW) | Rated pressure (Mpa) | Rated output temperature(℃) | Rated return water temperature(℃) | Thermal efficiency(%) | Fuel comsumption(Kg/h) | Exhaust temperation(℃) | max transportation weigh(t) | |

| DZL0.7 | 0.7 | 0.7 | 95/115 | 70 | >80 | 181 | <130 | 10 | |

| DZL1.4 | 1.4 | 1.0 | 95/115 | 70 | >80 | 370 | <130 | 22.5 | |

| DZL2.8 | 2.8 | 1.0 | 95/115 | 70 | >80 | 727 | <130 | 26.5 | |

| DZL4.2 | 4.2 | 1.0 | 95/115 | 70 | >80 | 1080 | <130 | 35.7 | |

| DZL5.6 | 5.6 | 1.0 | 95/115 | 70 | >80 | 1390 | <130 | 40.2 | |

| DZL7.0 | 7.0 | 1.0 | 95/115 | 70 | >80 | 1726 | <130 | 25.6 | |

| DZL10.5 | 10.5 | 1.0 | 95/115 | 70 | >80 | 2530 | <130 | 18 | |

| DZL14 | 14 | 1.0 | 95/115 | 70 | >80 | 3390 | <130 | 19.9 | |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

Chinese

Chinese

English

English

.png)