- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- DHL Water Tube Corner Tube Coal ...

- SHX Circulating Fluidized Bed Co...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Small Solid Fuel Coal Heating Bo...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg HFO Diesel Fired Thermal...

- Solid Fuel Coal Wood Biomass Fir...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- Horizontal Coal Biomass Thermal ...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Vertical Coal Wood Biomass T...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

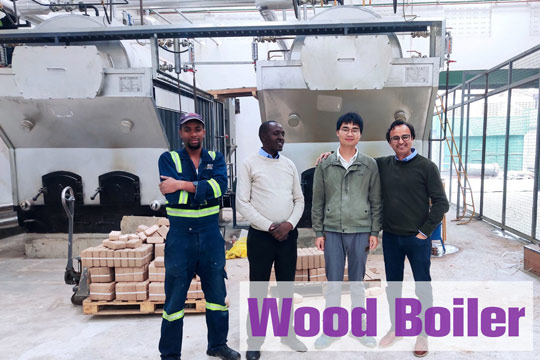

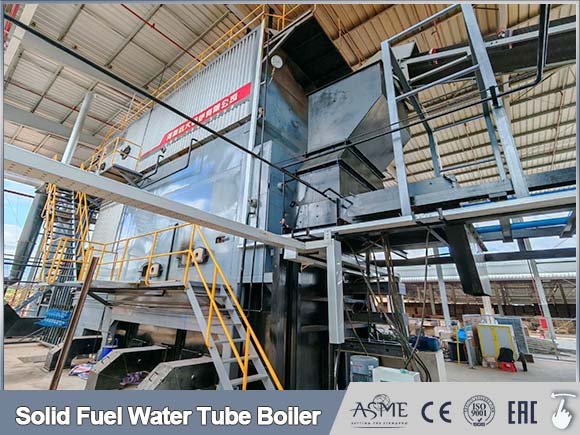

Briquette Coal Biomass Wood Hot Water & Steam Boiler

- Our Products:Steam Boiler, Steam Generator, Hot Water Boiler, Thermal Oil Boiler, Thermic Fluid Heater, Hot Air Furnace

- Capacity:100kg-20000kg, 100kw-14000kw

- Fuel:Briquette, Coal, Biomass, Wood, Husk, Solid Waste

- Use:Industries in food, juice, dairy products, paper, textile...

- Manufacture Standard:GB ISO CE ASME DOSH EAC

Industrial Briquette Boiler 0.3ton-50ton

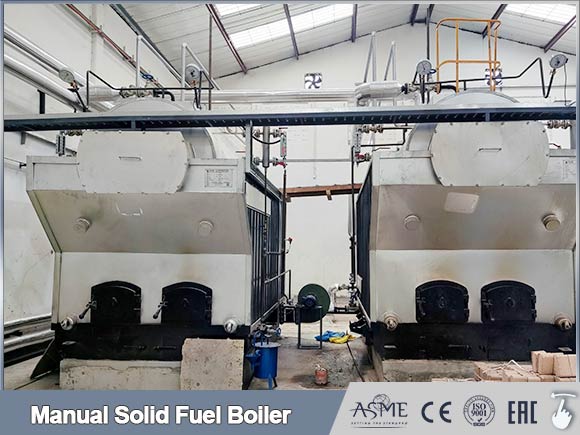

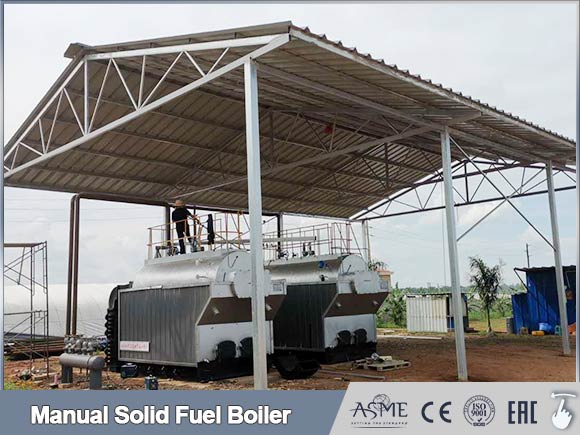

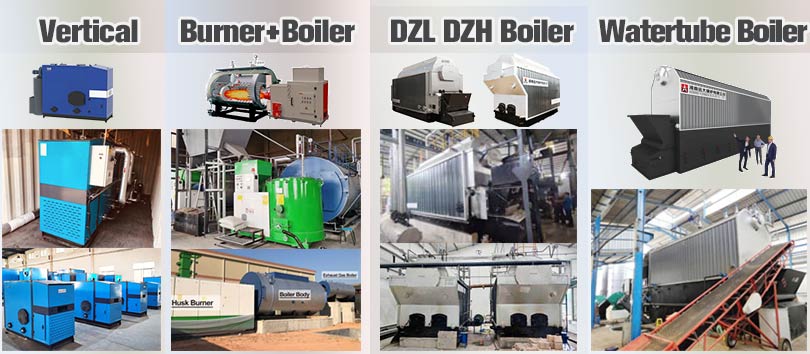

Briquette Fired Boiler, in manual-feeding or automatic-feeding. (Hot water or Steam generation Boiler)

What's the briquette ? Biomass briquettes are made from organic materials such as agricultural residues, wood chips, sawdust, or other biomass materials compressed into compact blocks.

Most Popular DZL Briquette Boiler

DZH series Travelling Grate Briquette Boiler

1) Horizontal fire-tube & water-tube boiler, manual-feeding works, using travelling grate stoker combustion system, It has strong fuel adaptibility for all agro waste, long life span.

2) DZH Briquette Boiler is equipped with automatic controls and mechanisms for air distribution, and ash removal, contributing to ease of operation and efficiency.

Available to burning all kinds of solid waste, biomass waste, coal cahrcoal, briquette.

Features Design Advantages

1. Smoke and dust separator chamber

Separate smoke and dust according to inertia,reduce the original effluent concentration of soot.

2. Optimized design CAD

Choose the best furnace from dozens of options,improve economical efficiency.

3. Convex tube plate

1) Improve tube plate flexibility, so as to reduce the heating stress of welded sew at the pipe end.

2) Prevent tube plate cracking, cancel bracing,simplify the structure.

4. Large size of simple circulation loop drop pipe and lower set box

Increase the flow rate of water on water cooling wall in order to prevent subcooled boiling. To prevent pipe explosion,Increase the reliability of water cycle

5. New pattern of furnace arch

Strengthen the combustion, could burn kinds of fuel: wood, coal and biomass, improve combustion efficiency.

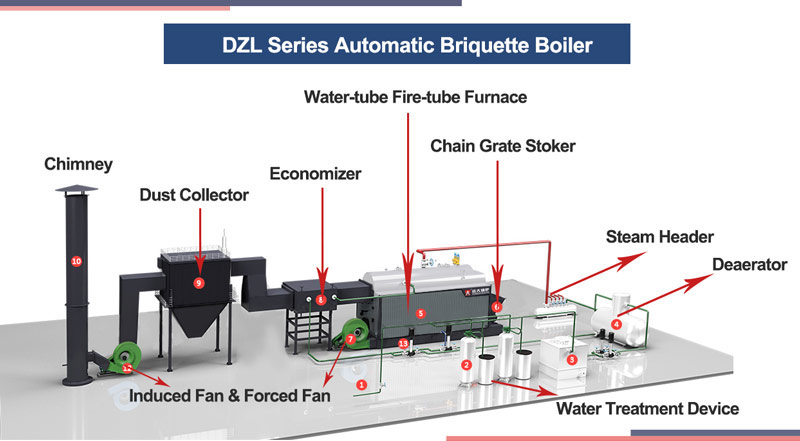

Product Automatic briquette boiler

DZL Automatic briquette boiler, use chain grate stoker combustion device, higher thermal efficiency & saving labor works.

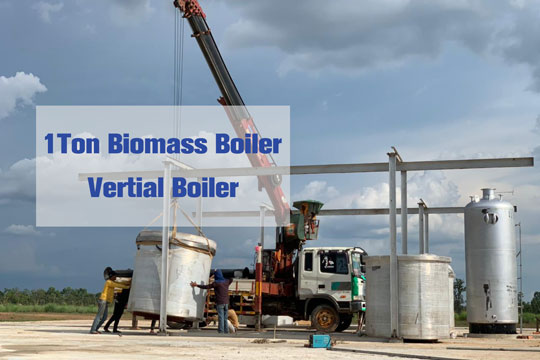

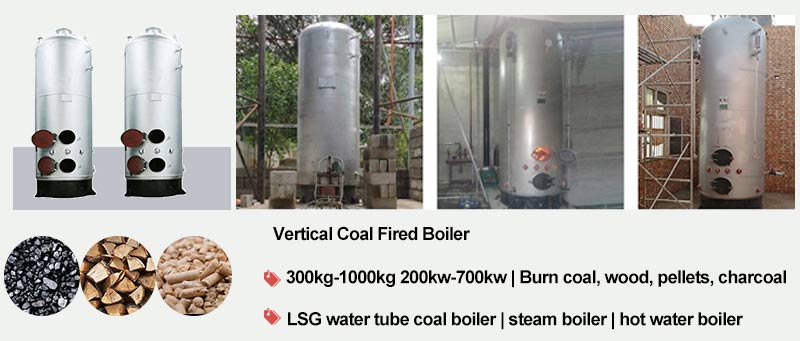

Product Vertical boiler

Small solid fuel coal charcoal wood boiler.

Our Boiler Strict Quality Control

1. Strength calculation report with applied materials information.

2. Hydraulic test report: ensure the standard working pressure and safety.

3. 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod.

4. 100% X-ray inspection report (welding seam): to ensure the quality of the entire boiler.

5. Third-party inspection report: by Zhoukou Institute of Special Equipment Inspection & Technical Research.

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

About us Yuanda Boiler

1. All products Certified With ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

2. Our company established since 1956, over 65 years manufactureing experiences, 15 Years export experience.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 103 countries all over the world, trustable quality & services for lifespan.

| DZH / DZH Series Briquette Boiler Parameter Table | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Rated capacity(t/h) | Rated pressure (Mpa) | Rated steam temperature(℃) | feed temperature(℃) | Thermal efficiency(%) | Boiler water volume(m³) | Exhaust temperation(℃) | Fuel comsumption(Kg/h) | max transportation weigh(t) |

| DZH1 | 1 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 3.15 | 127.25 | 192.32 | 9 |

| DZL1 | 1 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 3.15 | 113.34 | 190.42 | 13.5 |

| DZH2 | 2 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 4.75 | 126.41 | 386.47 | 15 |

| DZL2 | 2 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 4.77 | 106.34 | 393.77 | 22 |

| DZH4 | 4 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 7.7 | 137.25 | 782.29 | 18.5 |

| DZL4 | 4 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 8.2 | 124.49 | 756.89 | 27.6 |

| DZH6 | 6 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 7.4 | 146.83 | 1169.57 | 25 |

| DZL6 | 6 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 8.1 | 137.29 | 1148.68 | 35 |

| DZL8 | 8 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 9.6 | 141.06 | 1602.44 | 38 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

English

English

.png)