- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- DHL Water Tube Corner Tube Coal ...

- SHX Circulating Fluidized Bed Co...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Small Solid Fuel Coal Heating Bo...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg HFO Diesel Fired Thermal...

- Solid Fuel Coal Wood Biomass Fir...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- Horizontal Coal Biomass Thermal ...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Vertical Coal Wood Biomass T...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

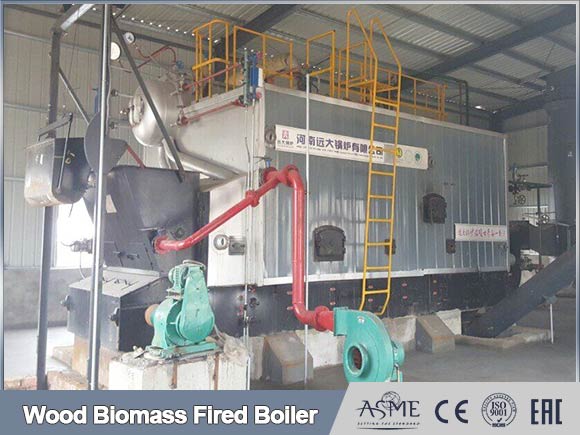

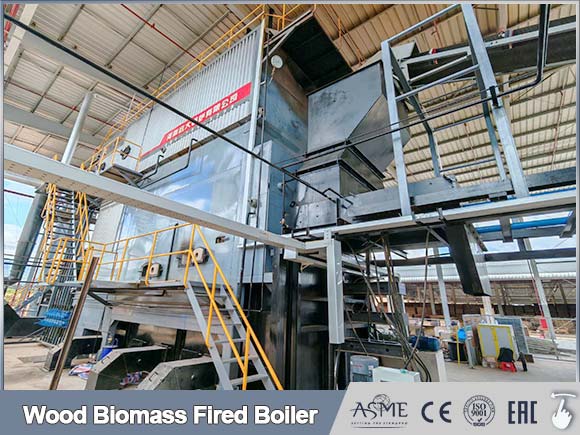

Bagasse Fired Boiler

- Our Products:Steam Boiler, Hot Water Boiler, Thermal Oil Boiler, Hot Air Furnace

- Capacity:1ton-120ton

- Pressure :0.1mpa-4.5mpa

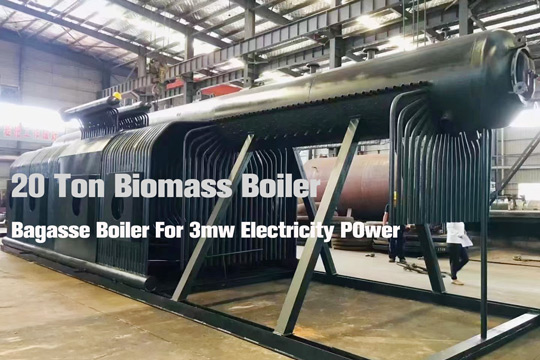

- Usage:For Factory productions process, Power generation

- Manufacture Standard :GB, ISO, CE, ASME, DOSH, EAC

Bagasse Fired Boiler Saturated or Superheated

Industrial Bagasse Boiler, High-Efficiency Steam Solutions for Biomass Energy.

Bagasse boiler is a high-efficiency biomass-fired steam boiler specially designed for burning bagasse (sugarcane residue).

Converting agricultural waste to steam and power, helping sugar factories and biomass power plants reduce fuel cost and carbon emissions.

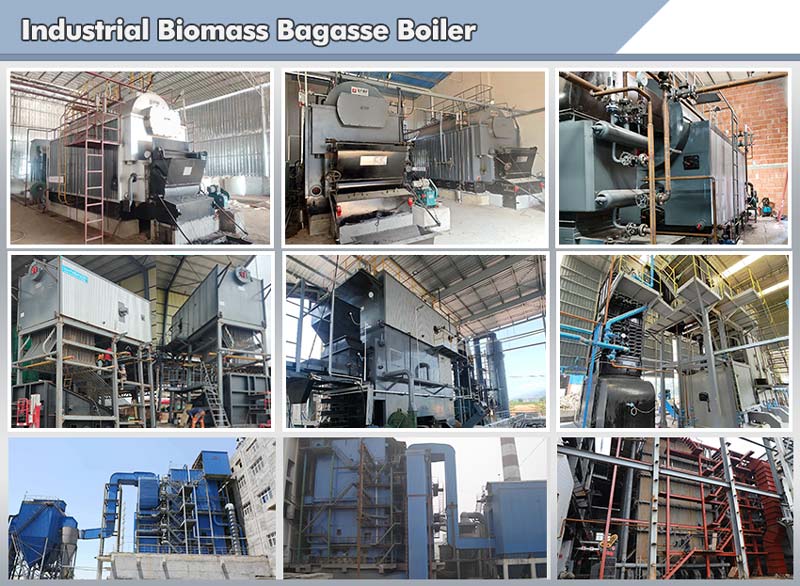

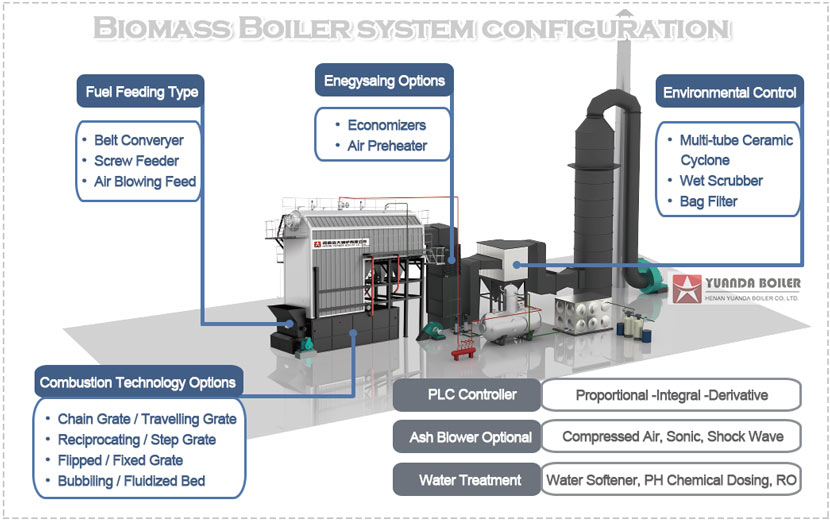

Bagass Boiler System Customized As Required

High Thermal Efficiency – Advanced combustion design ensures optimal heat recovery, reducing fuel consumption and operating costs.

Fuel Flexibility – Designed to handle bagasse with varying moisture content, optionally compatible with other biomass fuels.

Eco-Friendly Compliance – Low-emission technology helps meet environmental standards and supports carbon-neutral goals.

Robust & Long-Lasting – Built with premium materials to withstand high-temperature, corrosive environments, ensuring years of reliable service.

Automated Control Systems – User-friendly PLC-based controls enable easy operation, real-time monitoring, and safety management.

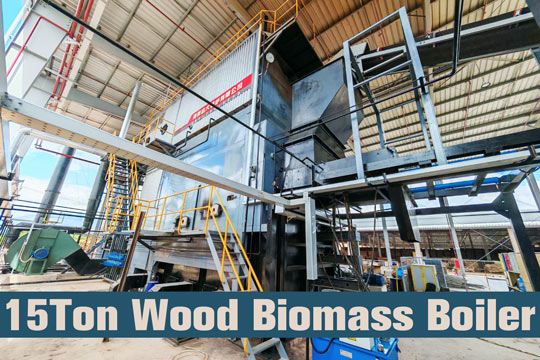

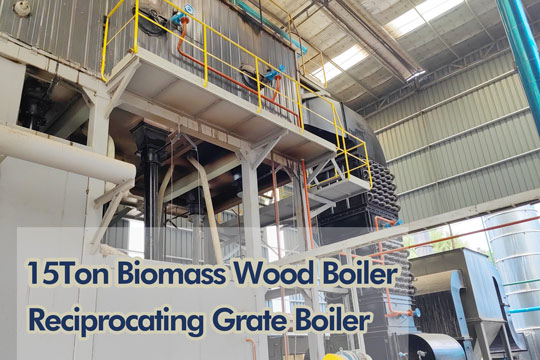

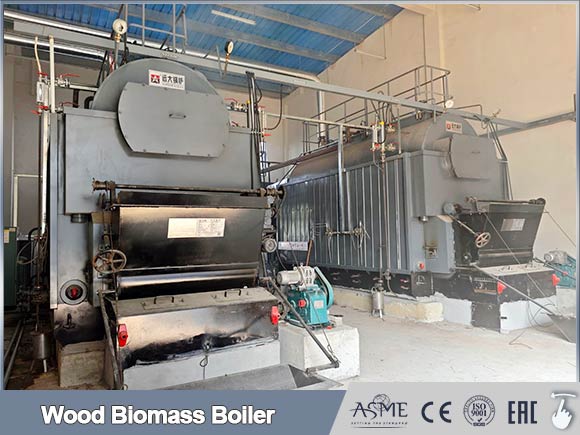

Bagasse Boiler Projects

Reliable, high-pressure steam from sugarcane waste—engineered for durability, efficiency, and maximum fuel flexibility.

Get a Customized Bagasse Boiler Solution

Our engineers will design a tailor-made bagasse boiler system based on your bagasse characteristics, steam demand and power generation requirement.

Contact Email: shirley@yuanda-boiler.com

Whatsapp: +8618236986701

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

About us Yuanda Boiler

1. All products Certified With ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

2. Our company established since 1956, over 70 years manufactureing experiences, 15 Years export experience.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 135 countries all over the world, trustable quality & services for lifespan.

| SZW Series Steam Boiler Technical Parameter Table | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Rated capacity(t/h) | Rated pressure (Mpa) | Rated steam temperature(℃) | feed temperature(℃) | Thermal efficiency(%) | Boiler water volume(m³) | Exhaust temperation(℃) | Fuel comsumption(Kg/h) | max transportation weigh(t) |

| SZW2 | 2 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >83.13 | 6.76 | 130.7 | 385.8 | 22 |

| SZW4 | 4 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >84.23 | 5.1 | 142 | 807 | 29 |

| SZW6 | 6 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >84.81 | 8.4 | 142 | 1209 | 34 |

| SZW8 | 8 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >85.02 | 9.4 | 149.1 | 1563.9 | 40.5 |

| SZW10 | 10 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.2 | 8.35 | 152.7 | 2149.3 | 24 |

| SZW12 | 12 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.56 | 12.8 | 148.7 | 2399.7 | 37 |

| SZW15 | 15 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.29 | 15.2 | 149.8 | 2568.4 | 24.7 |

| SZW20 | 20 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.8 | 15.5 | 147.4 | 4266.9 | 26 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

English

English

.png)