- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- DHL Water Tube Corner Tube Coal ...

- SHX Circulating Fluidized Bed Co...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Small Solid Fuel Coal Heating Bo...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg HFO Diesel Fired Thermal...

- Solid Fuel Coal Wood Biomass Fir...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- Horizontal Coal Biomass Thermal ...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Vertical Coal Wood Biomass T...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

Biomass Pellets Wood Pellets Steam Generator Boiler & Biomass Boiler Steam Turbine Generator

- Our Products:Steam Boiler, Steam Generator, Hot Water Boiler, Thermal Oil Boiler, Thermic Fluid Heater, Hot Air Furnace

- Steam Generator:100kg-10000kg, 100kw-7000kw

- Fuel:Biomass wood pellets, wood chips, bagasse, ricehusk, etc

- Manufacture Standard :GB, ISO, CE, ASME, DOSH, EAC

- Contact Info:shirley@yuanda-boiler.com

Steam Generator Boiler #steam_generation #electric_generation

Yuanda Boiler Global Sales Cover 132 Countries, Qualified By ISO CE ASME DOSH EAC.

Steam Generation #Biomass Pellet Steam Generator

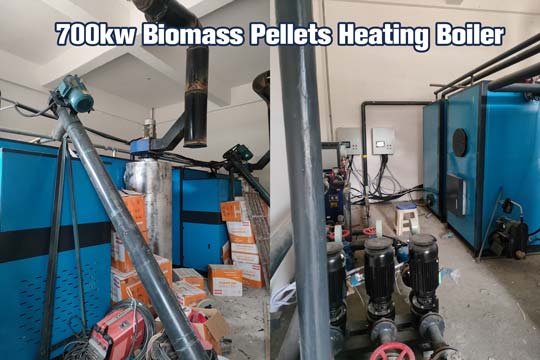

Automatic Biomass Pellets Steam Generator Boiler, inner water-tube & fire-tube heating, compact structure, small size, low noise, high thermal efficiency, modular integrity, good stability, movable type, able to connect with soft or hard pipes, easy to install etc.

Steam Capacity in 100kg/hour 200kg/hour 300kg/hour 500kg/hour 1000kg/hour 2000kg/hour

1. Energy Saving: Cheap biomass energy will help saving cost, with a low biomass consumption cost.

2. Efficienct Heat Exchange: Inner structure using water-tube & fire-tube transferring heat, thermal efficiency up tp 85%.

3. Flexible Assembly: Cause its small size appearance, available for nearby installation, it will help save little heat loss in pipelines.

4. Easy Into Use: It don't need set a boiler room, simple to install, one-botton start up/off, automatic ignition, auto-control system.

5. Intelligent Control: Automatic control system for work-pressure, water-level, biomass fuel feeding, combustion stage.

6. Modular Integrated Design: Compact structure, beauty appareance, light weight, available to move everywhere.

Electric Generation #Wood Biomass Boiler & Turbine Generator

Steam Boiler & Turbine Generator System, For Electricity Generation

SZL/SZW Series Water Tube Biomass Boiler, it is double drums and water tube boiler, scientifically design stove furnace to reach a higher thermal efficiency and energy saving, also environment protection

Steam Boiler Capacity: 1ton-50ton/hour

Power Generation: 100kw-10000kw

Fuel: Biomass, wood waste, pellets, palm kernel shells, palm shells fibre, rice husk, firewood, sawdust, woodchips, coconuts peanuts shells...

Based on the characteristics of biomass fuel you use, we will design the best suitable combustion device for you. If you can share the biomass characteristic, including Calorific value, Volume size, Moisture, Ash melting point, Component analysis and ash analysis, then we could supply best solution as soon as possible.

#Choose Steam Boiler For Electric Power

Based on steam turbine parameter, we can get boiler details including steam temperture, steam pressure, steam flow.

If you have chosen the steam turbine, please share its specifications.

If you don't have chosen one, we could give recommend according to electricity generation capacity.

Contact Email: shirley@yuanda-boiler.com

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

About us Yuanda Boiler

1. Our company established since 1956, over 65 years manufactureing experiences, 15 Years export experience.

2. Qualified by ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 132 countries all over the world, trustable quality & services for lifespan.

| Technical Parameter Sheet of Biomass Steam Generator | |||||||

|---|---|---|---|---|---|---|---|

| Model | LSS-0.12-0.6 | LSS-0.15-0.6 | LSS-0.2-0.7 | LSS-0.3-0.7 | LSS-0.5-0.7 | LSS-0.75-0.7 | LSS-1.0-0.7 |

| Rated steam capacity(Kg/h) | 120 | 150 | 200 | 300 | 500 | 750 | 1000 |

| Rated working pressure(Mpa) | 0.6 | 0.6 | 0.6 | 0.7 | 0.7 | 0.7 | 0.7 |

| Induced fan power(W) | 250 | 370 | 550 | 550 | 750 | 2200 | 4000 |

| Fd fan power(W) | 85 | 120 | 120 | 330 | 500 | 500 | 500×2 |

| Feeding motor power(W) | 250 | 250 | 250 | 250 | 250 | 250 | 250 |

| Pump power(w) | 750 | 750 | 750 | 1100 | 1500 | 2200 | 2200 |

| Power consumption(KW/h) | 1.34 | 1.49 | 1.67 | 2.23 | 3 | 5.15 | 7.45 |

| Thermal efficiency(%) | 85 | 85 | 85 | 85 | 85 | 85 | 85 |

| Fuel consumption(Kg/h) | 17 | 22 | 29 | 43 | 58 | 108 | 158 |

| Safety valve(Mpa) | 0.58 | 0.58 | 0.58 | 0.68 | 0.68 | 0.68 | 0.68 |

| Overall dimensions(mm) | 1700×650×1550 | 1700×700×1650 | 1850×750×1700 | 2000×1320×1800 | 2470×1480×1940 | 1860×1350×2200 | 2100×1650×2750 |

| Dust collector(mm) | Φ520×1350 | Φ550×1455 | Φ550×1455 | Built in dedusting | Built in dedusting | Φ755×2000 | Φ755×2000 |

| Shipping weight(kg) | 728 | 880 | 980 | 1480 | 2000 | 2500 | 2900 |

| Remarks | This product is in the process of continuous improvement. The above parameters may change. Specifically, they are based on physical objects. We apologize for the inconvenience caused to you. | ||||||

| Calorific value of biomass particles: 4000Kcal/KG | |||||||

English

English

.png)