- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- DHL Water Tube Corner Tube Coal ...

- SHX Circulating Fluidized Bed Co...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Small Solid Fuel Coal Heating Bo...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg HFO Diesel Fired Thermal...

- Solid Fuel Coal Wood Biomass Fir...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- Horizontal Coal Biomass Thermal ...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Vertical Coal Wood Biomass T...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

Vertical Biomass Wood Boiler Water Heater & Steam Boiler

- Our Products:Steam Boiler, Steam Generator, Hot Water Boiler, Thermal Oil Boiler, Thermic Fluid Heater, Hot Air Furnace

- Capacity:100kg-10000kg, 70kw-7000kw

- Fuel:Biomass, wood, coal, charcoal, briquette, waste jute

- Usage:For Industrial water heating system, Factory productions process

- Manufacture Standard :GB, ISO, CE, ASME, DOSH, EAC

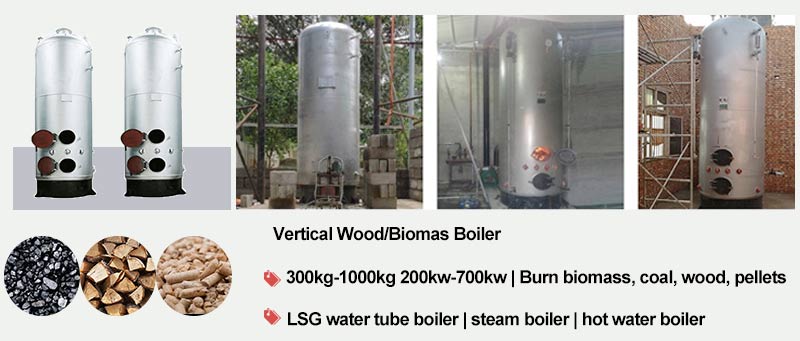

Vertical Solid Fuel Boiler

Global Sales & Service Cover 132 Countries, With ISO CE ASME DOSH EAC Certificates.

Vertical solid fuel (coal, wood, biomass) steam boiler and hot water boiler.

Capacity: 41kw-1400kw, 100kg-2000kg/hour

Introduce LSG Series Solid Fuel Boiler

LSG series vertical wood/biomass boiler, suitable for burn biomass, wood, coal, charcoal, pellets, waste jute. Could use as steam boiler, hot water boiler.

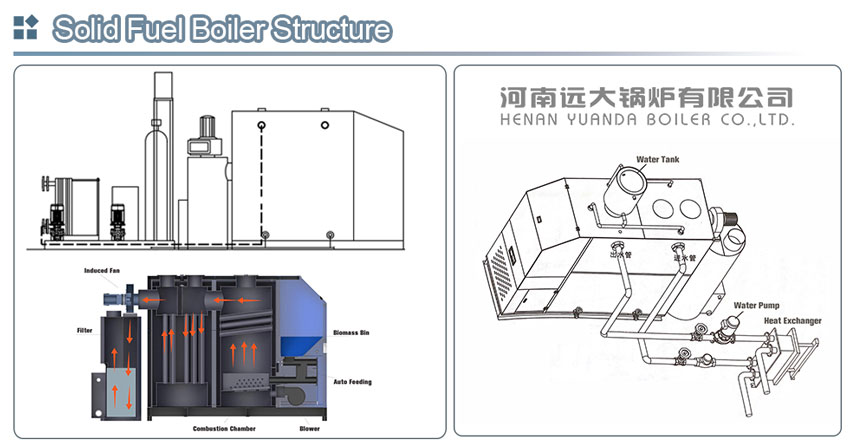

Structure: Boiler body made of U-circle, boiler drum, shell cover, furnace, horizontal water tube, vertical tube, convection tubes etc. pressure parts. Set manhole on shell cover, convenient for boiler maintenance and clean.

Capacity: 500kg 1000kg 350kw 700kw

LSG Boiler Advantages

Vertical water tube boiler, with fixed grate combustion stoker.

1. Strong Fuel Adaptability

Available to use all solid waste, coal, wood, biomass, waste jute.

2. Simple structure

Simple design, easy to install. Small area occupied, low investment cost.

3. Easy to install & operate

Low pressure operation, safety and quick run-on heating water, generate steam.

4. Low Cost

Double-deck fire grate combustion chamber design, flue gas burn twice, low fuel consumption

Related Small Coal Biomass Boiler

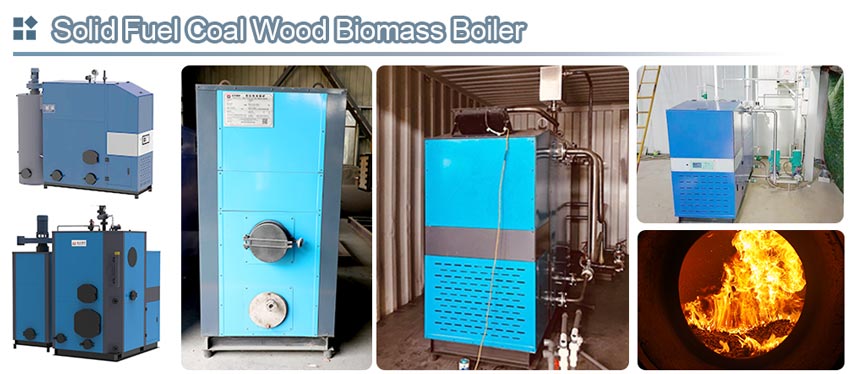

CLSS Solid Fuel Steam/Hot Water Boiler

Fuel: coal, wood, biomass, pellets

Capacity: 41kw-1400kw, 200kg-20000kg

Coal Biomass Boiler Features

1. Energy Saving

Compared to expensive electricity power, biomass energy will help saving cost, with a low biomass consumption cost.

2. Efficienct Heat Exchange

Inner structure using water-tube & fire-tube transferring heat, thermal efficiency up tp 85%.

3. Flexible Assembly

Cause its small size appearance, available for nearby installation, it will help save little heat loss in pipelines.

4. Easy Into Use

It don't need set a boiler room, simple to install, one-botton start up/off, automatic ignition, auto-control system.

5. Intelligent Control

Automatic control system for work-pressure, water-level, biomass fuel feeding, combustion stage.

6. Modular Integrated Design

Compact structure, beauty appareance, light weight, available to move everywhere.

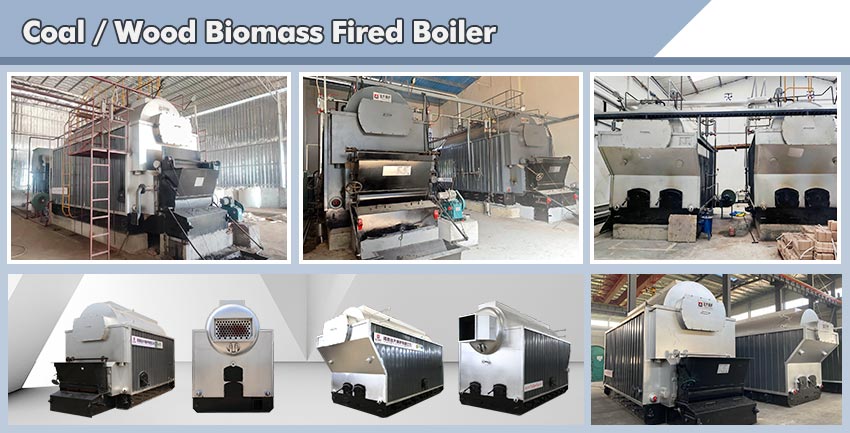

Related Horizontal Coal/Biomass Boiler

Horizontal solid fuel boiler 1ton-50ton/h, 700kw-28000kw.

Fuel: coal, wood, biomass, bagasse, rice husk, cashew shells, palm shells, coconut shells...

Boiler types: Chain grate boiler, Fixed grate boiler, Travelling grate boiler, Reciprocating grate boiler.

Our Boiler Strict Quality Control

1. Strength calculation report with applied materials information.

2. Hydraulic test report: ensure the standard working pressure and safety.

3. 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod.

4. 100% X-ray inspection report (welding seam): to ensure the quality of the entire boiler.

5. Third-party inspection report: by Zhoukou Institute of Special Equipment Inspection & Technical Research.

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

About us Yuanda Boiler

1. All products Certified With ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

2. Our company established since 1956, over 65 years manufactureing experiences, 15 Years export experience.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 135 countries all over the world, trustable quality & services for lifespan.

| Model | Rated evaporation(T/H) | Rated pressure (Mpa) | Saturation temperature(℃) | Thermal efficiency(%) | Water capacity(L) | Fuel consumption(Kg/H) | power supply(V) |

|---|---|---|---|---|---|---|---|

| LSG0.08-0.7 | 0.08 | 0.7 | 170 | ≥90 | 29.5 | 12 | 220 |

| LSG0.12-0.7 | 0.12 | 0.7 | 170 | ≥90 | 29.5 | 17 | 220 |

| LSG0.16-0.7 | 0.16 | 0.7 | 170 | ≥90 | 29.5 | 25 | 220 |

| LSG0.23-0.7 | 0.23 | 0.7 | 170 | ≥90 | 29.5 | 33 | 220 |

| LSG0.30-0.7 | 0.3 | 0.7 | 170 | ≥90 | 47.5 | 50 | 220 |

| LSG0.50-0.7 | 0.5 | 0.7 | 170 | ≥90 | 29.5 | 75 | 220 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||

English

English

.png)

.jpg)