- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- DHL Water Tube Corner Tube Coal ...

- SHX Circulating Fluidized Bed Co...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Small Solid Fuel Coal Heating Bo...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg HFO Diesel Fired Thermal...

- Solid Fuel Coal Wood Biomass Fir...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- Horizontal Coal Biomass Thermal ...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Vertical Coal Wood Biomass T...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

.jpg)

.jpg)

Vacuum Hot Water Boiler

- Capacity:300KW-28000KW

- Thermal efficiency:>98%

- Water temperature:55°C-95°C

- Fuel:Natural gas, lpg, diesel, heavy oil, exhaust gas, dual fuel, etc

- Application:Center heating, Greenhouse, Hospital, Swimming pool, etc

ZWNS Series Vacuum Hot Water Boiler

Themal capacity: 350kw-5600kwAavailable fuel: Natural gas, lpg, oil, diesel

Vacuum hot water boiler adopts principle of water-fire tube boiler, SU304S stainless steel heat exchanger, high heat transfer efficiency of flue gas, compact structure, high efficiency and energy saving, ultra low NOx emission and small volume.

The vacuum boiler operates under negative pressure and has multiple protection functions, It is safe and reliable and never explodes. It has exquisite appearance, convenient installation, convenient maintenance and no need for supervision.

1. Safety:

There is no danger of expansion, explosion or rupture during negative pressure operation;

2. Long service life:

The heat medium water heat exchange system is used, there is no scaling and corrosion phenomenon, the boiler maintenance and after-sales problems are reduced, and the service life of the boiler is greatly increased;

3. Exemption from inspection products:

Negative pressure operation products, the relevant state departments are exempt from inspection and supervision;

4. Small size:

Can be placed in the basement and roof, more conducive to the boiler room configuration, modular parallel connection;

5. Environmental protection:

The measured minimum emission of NOX is 20mg/m3, in line with the most stringent environmental protection standards;

6. Energy saving:

The measured air consumption of the 0.7MW hot water boiler in one hour is <60m3, which is far lower than the industry data;

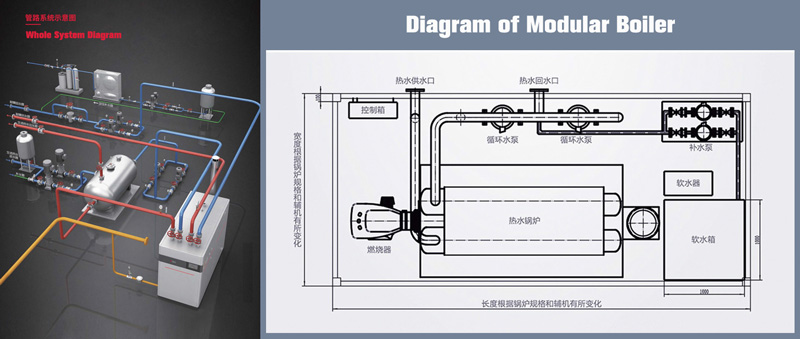

Modular Vacuum Hot Water Boiler

"Automatic" "Environmental" "Easy Install" "Easy Operate" "Clean-energy Boiler"

Introduction: YDB Series Modular Hot Water Boiler System solutions are pre-manufactured, modular buildings, with hot water boiler and pumping equipment, it's environmentally friendly equipment (with low NOx <30mg).

Modular hot water boiler plant provides a building owner with a completely integrated solution for any industrial or commercial facility needs. Yuanda engineering and manufacturing experience with steam systems provides us with the ability and expert knowledge required to provide you with a complete steam generating system for your facility.

Working Principle Modular Hot Water Boiler

1. Boiler combustion chamber structure adopts full-membrane wall natural circulation water tube single-return structure. The burner, control cabinet, condenser, valve instrument, etc. have been installed and debugged before leaving the factory, they are integrated into a unit form before leaving the factory.

2. Unique water-tube single-return structure, compact water tubes arrangement, higher heat transfer coefficient of flue gas, the normal operation water volume of boiler is only one-third of fire tube boiler, make boiler heat up faster. The boiler adopts post-premixed combustion technology, and the combination of air cooling and water cooling reduces the flame temperature and achieves ultra-low nitrogen emissions.

Advantages Modular Hot Water Boiler

1. More energy-saving: Make use of the professional level of the boiler room and make overall planning to make the boiler, auxiliary machine and control effectively match to achieve the best effect

2. More guaranteed quality: professional factory assembly, more guaranteed material quality and assembly quality

3. The construction period can be shortened: It can be produced by using the process facilities of the factory, and only need to connect the external water inlet and outlet pipes on site, and the installation period can be shortened by more than one third.

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

About us Yuanda Boiler

1. Our company established since 1956, over 65 years manufactureing experiences, 15 Years export experience.

2. Qualified by ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 132 countries all over the world, trustable quality & services for lifespan.

| Model |

|

|

|

ZWNS | ZWNS | ZWNS | ZWNS | ZWNS | ||

|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

0.7 | 1.05 | 1.4 |

|

2.1 | ||

| Heat output | MW |

|

|

|

0.7 | 1.05 | 1.4 |

|

2.1 | |

|

×104 |

|

|

|

60 | 90 | 120 |

|

180 | ||

| Kcal/h |

|

|

|

|

|

|

|

|

||

| Meterial of heat exchanger |

stainless steel tube | |||||||||

| Working pressure of heat exchanger |

1.0 Mpa | |||||||||

| A-model heat exchanger | Application |

|

Apply to heating | |||||||

| Inlet/Outlet water temperature |

°C |

55/60(=5°C)

|

||||||||

| Hot water flow | m³/H | 40 | 60 | 80 | 120 | 180 | 240 | 300 | 360 | |

| B-model heat exchanger | Application |

|

Apply to heating, hot water circulation etc.

|

|||||||

| Inlet/Outlet water temperature |

°C |

50/60(=10°C)

|

||||||||

| Hot water flow | m³/H | 20 | 30 | 40 | 60 | 90 | 120 | 150 | 180 | |

| C-model heat exchanger | Application |

|

Apply to sanitary hot water,radiator heating circulation etc. |

|||||||

| Inlet/Outlet water temperature |

°C |

40/60 or 60/80(=20°C) |

||||||||

| Hot water flow | m³/H | 10 | 15 | 20 | 30 | 45 | 60 | 75 | 90 | |

| Hot water output per hour(10-60°C) |

T/H | 4 | 6 | 8 | 12 | 18 | 24 | 30 | 36 | |

| Cumbustion regulatin mode |

|

|

Full automatic single/double phase fire regulation | |||||||

| Fuel |

|

|

60#heavy oil/diesel/natural gas/LPG/Coal gas | |||||||

| Fuel consumption | 60#heavy oil | Kg/h | 22.8 | 34.2 | 45.6 | 68.4 | 102.7 | 136.9 | 171.1 | 205.3 |

| Diesel | Kg/h | 22 | 32.9 | 43.8 | 65.8 | 98.7 | 131.5 | 164.4 | 197.3 | |

| Natural gas | Nm³/h | 26.5 | 39.7 | 52.9 | 79.3 | 119 | 158.6 | 198.3 | 237.9 | |

| LPG | Nm³/h | 8.5 | 13.2 | 17.6 | 26.3 | 39.5 | 52.7 | 65.8 | 79 | |

| Coal gas | Nm³/h | 56.2 | 84.3 | 112.4 | 168.5 | 252.8 | 337.1 | 421.3 | 505.6 | |

| External dimension | Length | mm | 2440 | 3008 | 3360 | 3440 | 3536 | 4130 | 4408 | 4726 |

| Width | mm | 970 | 1140 | 1300 | 1440 | 1550 | 1550 | 1830 | 1830 | |

| Height | mm | 1490 | 1957 | 2200 | 2450 | 2500 | 2500 | 2968 | 2994 | |

| Weight |

|

T | 1.3 | 2.1 | 2.45 | 3.4 | 4.4 | 4.5 | 6.3 | 6.9 |

English

English

.png)