- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- DHL Water Tube Corner Tube Coal ...

- SHX Circulating Fluidized Bed Co...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Small Solid Fuel Coal Heating Bo...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg HFO Diesel Fired Thermal...

- Solid Fuel Coal Wood Biomass Fir...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- Horizontal Coal Biomass Thermal ...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Vertical Coal Wood Biomass T...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

Electric Thermal Oil Heater Boiler Thermic Fluid Heater

- Our Products :Steam Boiler, Steam Generator, Hot Water Boiler, Thermal Oil Boiler, Thermic Fluid Heater, Hot Air Furnace

- Heat Temperature:200°C-400°C

- Usage:In textile, bitumen, plywood, asphalt, plastics, foods, heating tanks, heating crude oil, oil refinery...

- Manufacture Standard :GB, ISO, CE, ASME, DOSH, EAC

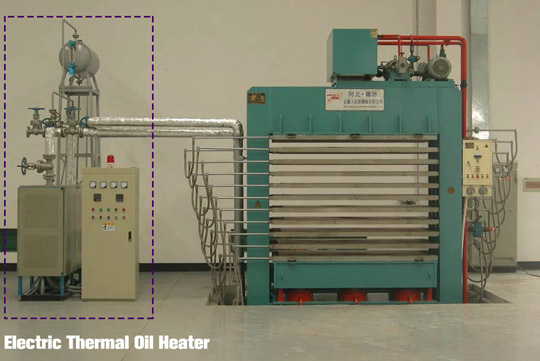

Electric oil heater boiler

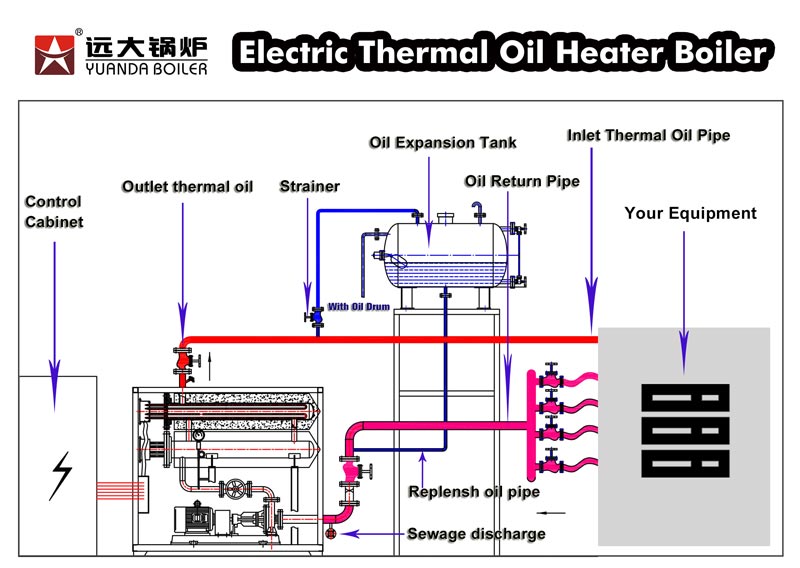

YDW series electric thermal oil heater, it will use electricity as the heat source, thermal oil as the heat carrier, adopt high-temperature-resistant circulating oil pump to carry out the forced circulation, high-temperature thermal oil will transfer heat energy to the end-user equipment, releasing part of the heat energy, thermal oil will return to heater furnace for reheating. Endless cycling the process.

Electric Oil Heater Advantages

1. It can run at a lower pressure and get a higher operating temperature.

2. Electric oil heater can get the stable heating and precise temperature.

3. At all levels of load, thermal efficiency is maintained at optimum levels.

4. Electric oil heater has complete operational control and security monitoring devices.

5. The oil heaters help to save electricity, oil and water, and can recover investment in 3 to 6 months.

How electric oil heater work ?

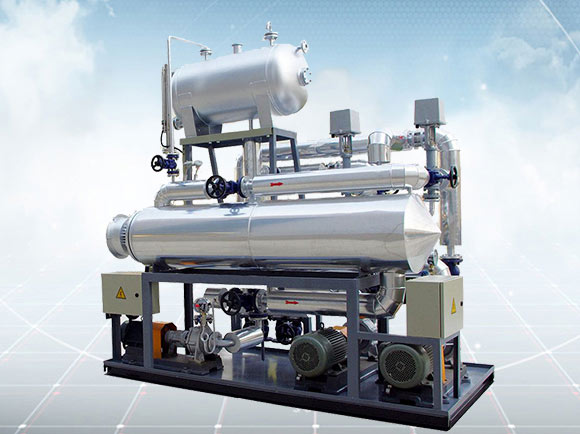

Electric thermal oil heater is a particular kind of forced circulation industrial heater that uses electric as power, and takes thermal oil as its medium. The pump in the system circulates thermal oil to heat using equipment, releasing heat there and back to the heater for reheat again.It can be made as normal type or explosion proof type according to different safety level requirement.

What is thermal oil boiler ? it also said thermic fluid heater, hot oil heater. Mostly thermal oil boiler could use gas, diesel, coal, biomass electricity as heating power. Thermal oil boiler inner is transfer oil medium, transfer oil is forced into circulation heating system, circulating under specific pressure, heating temperature up to 350°C.

Plan A Gas/lpg/oil fired thermal oil boiler

1. YYQW horizontal three-coil structure thermal oil boiler, use gas/diesel burner supply heat, boiler body is composed of outer oil, middle oil, inner oil and rear oil. Heat transfer surface is formed by round coilers, sufficient arrangement, 100% safety

2. YQL vertical three-coil structure thermal oil boiler, it occupy small area in boiler room, same as horizontal boiler, its fully automatic and three coil design, 100% safety & low emission & high efficiency.

Remark: small capacity boiler could be installed perfect in a skid-mounted, put boiler and all accessories at a platform, easier to tranfer and use in anywhere you need it.

Plan B Coal/biomass/wood thermal oil boiler

1. YLW horizontal coal/biomass thermal oil boiler, it's square coil structure & chain grate combustion device, forced oil circulation system then output high-temp oil for heating use. Equipped with the perfect device for operation and safety test.

2. YGL vertical wood/coal thermal oil boiler, small occupation & easy installation & quick into using, inner coil sturcture for thermic oil circulating, output high temp. oil for use. Strong load oil heating boiler, ensure safety 100%.

Remark: small capacity boiler could be installed perfect in a skid-mounted, put boiler and all accessories at a platform, easier to tranfer and use in anywhere you need it.

Plan C Electric oil heater

Electricity heating oil boiler, suitable capacity in 30kw-1400kw, simple structure and easy to operate, you can move it to everywhere you need use.

| Model | Reted capacity | Rated pressure | Oil Volume | Dimension(MM) | Hot Oil Pump | Total Power | Weight | Oil Expansion Tank | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (KW) | (*104kcal/h) | (Mpa) | (L) | L | W | H | Flow(m³/h) | Lift(M) | Power(Kw) | Kw | Kg | L | |

| YDW10 | 10 | 0.8 | 0.6 | 15 | 1100 | 500 | 1100 | 6 | 27 | 1.5 | 11.5 | 200 | 100 |

| YDW18 | 18 | 1.5 | 0.6 | 23 | 1600 | 500 | 1250 | 6 | 27 | 1.5 | 19.5 | 200 | 130 |

| YDW24 | 24 | 2 | 0.6 | 28 | 1950 | 650 | 1450 | 12.5 | 30 | 3 | 27 | 350 | 150 |

| YDW36 | 36 | 3 | 0.6 | 48 | 1950 | 650 | 1450 | 12.5 | 30 | 3 | 39 | 350 | 200 |

| YDW48 | 48 | 4 | 0.6 | 48 | 1950 | 650 | 1450 | 18 | 40 | 5.5 | 53.5 | 350 | 230 |

| YDW60 | 60 | 5 | 0.6 | 52 | 1950 | 650 | 1450 | 18 | 40 | 5.5 | 65.5 | 350 | 230 |

| YDW70 | 70 | 6 | 0.6 | 60 | 2150 | 700 | 1750 | 30 | 48 | 7.5 | 77.5 | 550 | 280 |

| YDW90 | 90 | 7.5 | 0.6 | 68 | 2150 | 700 | 1750 | 30 | 48 | 7.5 | 97.5 | 550 | 280 |

| YDW120 | 120 | 10 | 0.6 | 105 | 2200 | 700 | 1880 | 30 | 48 | 7.5 | 127.5 | 750 | 300 |

| YDW150 | 150 | 12.5 | 0.6 | 195 | 2200 | 900 | 1880 | 30 | 48 | 7.5 | 157.5 | 750 | 300 |

| YDW180 | 180 | 15 | 0.6 | 230 | 2200 | 1000 | 1880 | 45 | 48 | 11 | 191 | 1200 | 320 |

| YDW240 | 240 | 20 | 0.6 | 260 | 2300 | 1000 | 1950 | 80 | 38 | 15 | 255 | 1200 | 350 |

| YDW300 | 300 | 25 | 0.6 | 358 | 2800 | 1200 | 2000 | 80 | 38 | 15 | 415 | 1750 | 450 |

| YDW500 | 500 | 40 | 0.6 | 510 | 2800 | 1500 | 2000 | 80 | 38 | 15 | 515 | 1850 | 550 |

| YDW700 | 700 | 60 | 0.6 | 638 | 3000 | 1800 | 2150 | 80 | 38 | 15 | 715 | 2200 | 650 |

| … | … | … | … | … | … | … | … | … | … | … | … | … | … |

| GYD1400 | 1400 | 120 | 0.6 | 2100 | 3600 | 2900 | 2150 | 80 | 85 | 37 | 1437 | 6500 | 1200 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||||||

English

English

.png)