- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- DHL Water Tube Corner Tube Coal ...

- SHX Circulating Fluidized Bed Co...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Small Solid Fuel Coal Heating Bo...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg HFO Diesel Fired Thermal...

- Solid Fuel Coal Wood Biomass Fir...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- Horizontal Coal Biomass Thermal ...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Vertical Coal Wood Biomass T...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

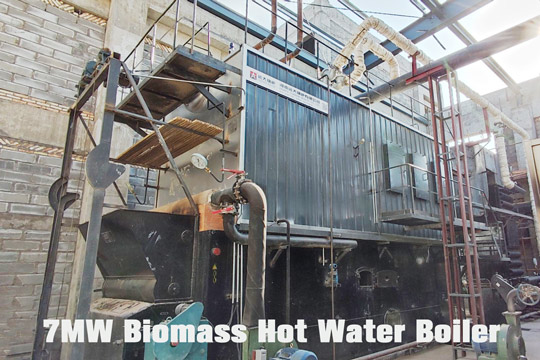

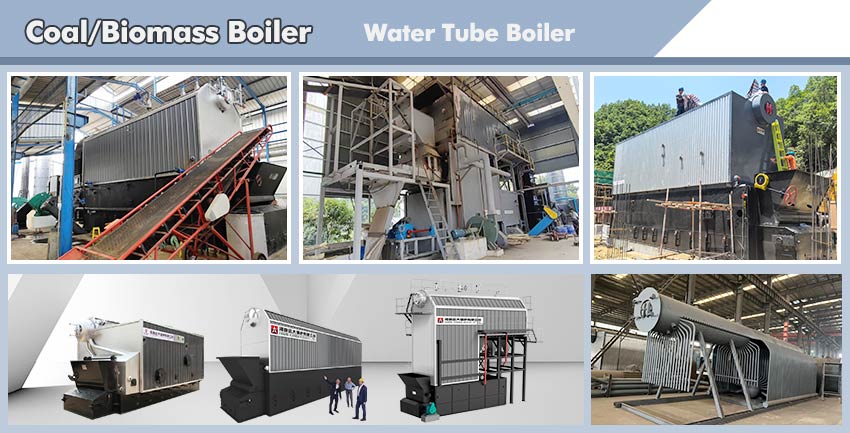

Coal Biomass Water Tube Hot Water Boiler

- Capacity:1.4mw-50mw

- Water Temperature:50-130°C

- Fuel:Biomass, coal, wood, ricehusk, bagasse...

- Application:For commercial use, industrial heating drying process

- Manufacture Code:ISO CE ASME EAC

Coal Biomass Hot Water Boiler

Heat Capacity: 1400kw to 35000kw

Available Fuel: coal, wood, biomass, pellet, ricehusk, palm kernel shells, sawdust, bagasse.

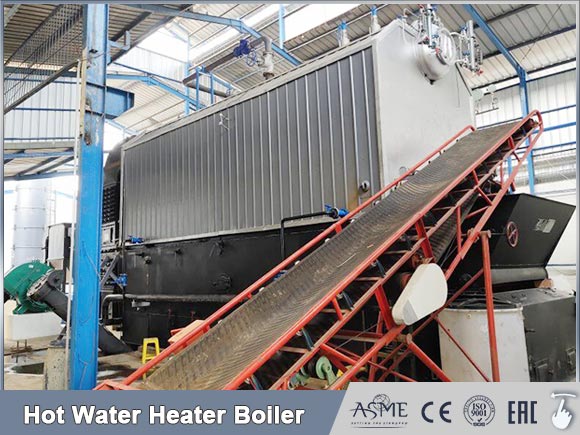

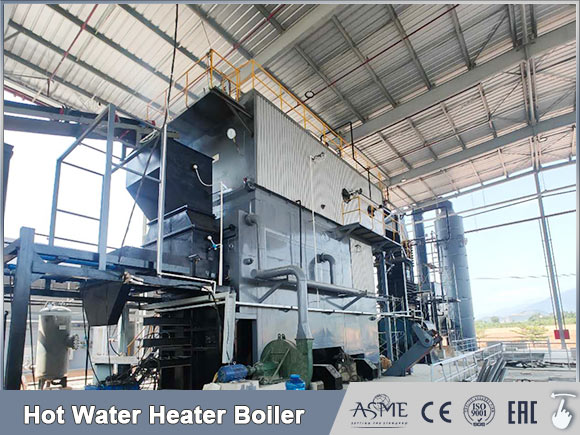

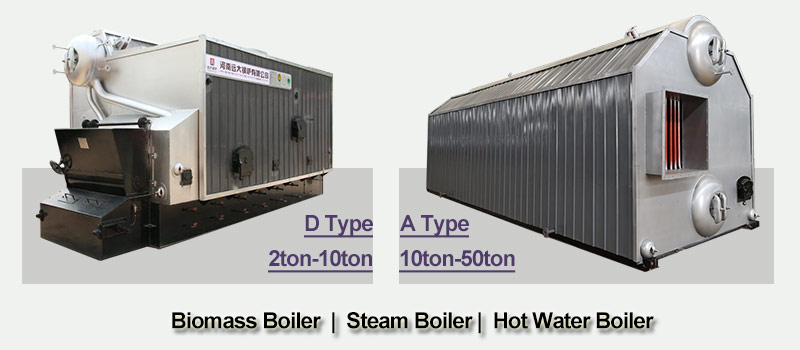

Hot Water Boiler

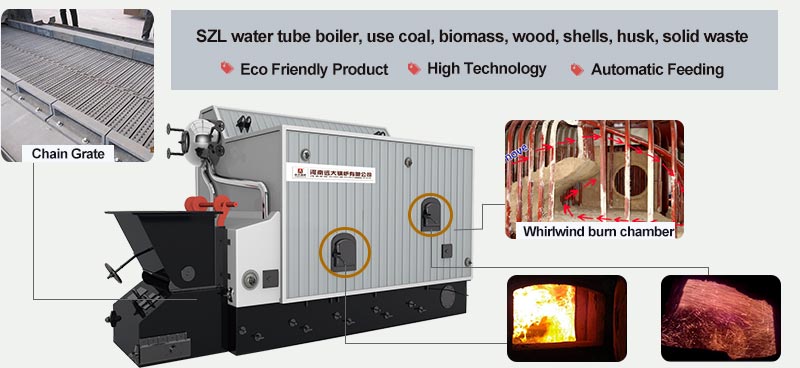

Yuanda SZL/SZW Series water tube boiler, adopt a double-drum offset furnace structure (D-type or A-type) and are available with chain grate or reciprocating grate stokers, delivering high efficiency, reliable operation, and eco-friendly, energy-saving performance.

Yuanda SZL Boiler Advantages:

1. With Built-in Steam Separator

2. High efficiency with various biomass waste fuels

2. With Built-in Air Distribution Piping inside arch

3. Resistance to Corrosion & Slagging Processing in Convection Heating Area

Technical Features SZL Boiler

Intelligent Combustion Control System

1. Multi-zone air distribution: Air is supplied in sections along the grate length, with independent airflow control for each zone.

2. Real-time oxygen monitoring: Combustion air is automatically adjusted based on flue gas oxygen content to maintain optimal combustion.

3. Layered temperature control: Different grate zones are temperature-controlled to prevent local overheating and slagging.

Anti-Slagging Design

1. Optimized front and rear arches: Enhance heat radiation and gas mixing for stable ignition.

2. Special grate bars: High-temperature and oxidation resistant, with clinker-breaking structure.

3. Multi-stage ash cleaning: Combination of mechanical cleaning and soot blowers keeps heating surfaces clean.

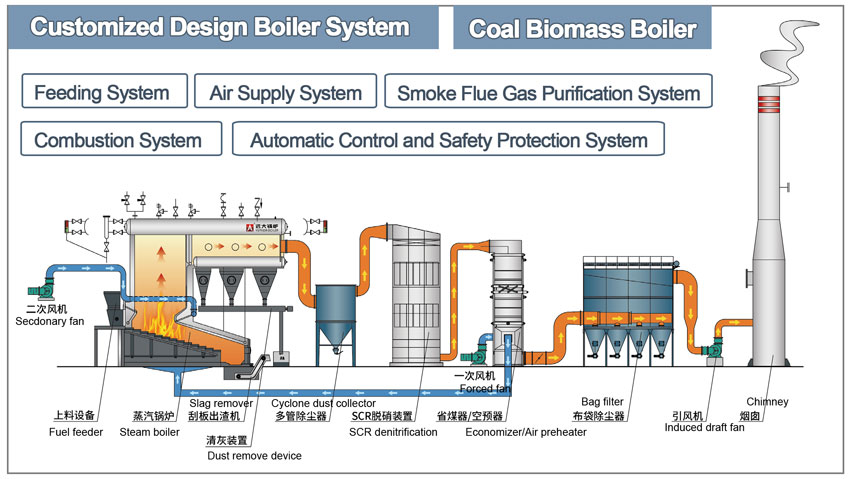

Environmentally Compliant Emissions

1. Low-NOx combustion: Air staging and flue gas recirculation reduce NOx formation.

2. High-efficiency dust removal: Multi-cyclone or bag filter options meet strict emission standards.

3. Fly ash reuse: Collected ash can be reused as potassium fertilizer raw material, supporting resource recycling.

Typical Projects

Yuanda Biomass Coal Boiler, Qulified by ISO CE ASME DOSH, Global Sale Service Cover 100+ Countries & Regions.

Yuanda Boiler Boilers Sale Service Already Cover 135 countries !

Why choos us ? Yuanda Boiler

1. Products Certificates Qualifications

Yuanda products comply with international boiler manufacturing inspection standards such as ISO ASME CE SGS DOSH EAC.

2. Professional & Trustable

Yuanda Boiler, has professional technical research and development team, mature production technician team, high-quality raw material suppliers, experienced installation engineer team (have been to more than 50 countries to be responsible for after-sales installation and commissioning services)

3. Yuanda Boiler Since 1956

Till now, Yuanda Boiler has a 66-year history of development, continuous innovation, continuous progress, and never stops. With a large number of loyal boiler users, the good reputation has also driven the promotion of the Yuanda brand, and the market share has been increasing.

4. Reliable Service For Life-time

Before-sale services | on-sale services | after-sale services. We always adhere to the principle of customer-oriented and customer service. Yuanda will provide life service for products forever, keep moving.

Our Boiler Strict Quality Control

1. All materials should be inspected before prodcution and each steel have its ID code which can trace its quality test.

2. 100% Non-Destructive Inspection report of steel plate tube & welding rod.

3. Hydraulic test: make sure strength and tightness of pressure parts.

4. Third part inspection report: By China Henan Boiler Inspection Institute.

| Water Tube Boiler Technical Parameter Table | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Rated capacity(MW) | Rated pressure (Mpa) | Rated output temperature(℃) | Rated return water temperature(℃) | Thermal efficiency(%) | Fuel comsumption(Kg/h) | Exhaust temperation(℃) | max transportation weigh(t) | |

| SZL1.4 | 1.4 | 0.7 | 95/115 | 70 | >80 | 181 | <130 | 10 | |

| SZL2.8 | 2.8 | 0.7 | 95/115 | 70 | >80 | 370 | <130 | 22.5 | |

| SZL4.2 | 4.2 | 1.0 | 95/115 | 70 | >80 | 727 | <130 | 26.5 | |

| SZL5.6 | 5.6 | 1.0 | 95/115 | 70 | >80 | 1080 | <130 | 35.7 | |

| SZL7 | 7 | 1.0 | 95/115 | 70 | >80 | 1390 | <130 | 40.2 | |

| SZL10.5 | 10.5 | 1.0 | 95/115 | 70 | >80 | 1726 | <130 | 25.6 | |

| SZL14 | 14 | 1.0 | 95/115 | 70 | >80 | 2530 | <130 | 18 | |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

English

English

.png)