- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- DHL Water Tube Corner Tube Coal ...

- SHX Circulating Fluidized Bed Co...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Small Solid Fuel Coal Heating Bo...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg HFO Diesel Fired Thermal...

- Solid Fuel Coal Wood Biomass Fir...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- Horizontal Coal Biomass Thermal ...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Vertical Coal Wood Biomass T...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

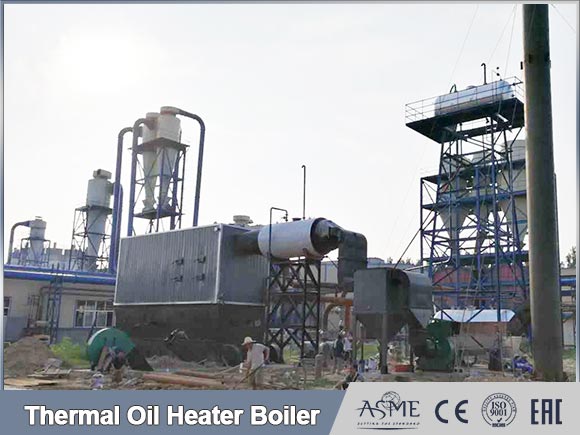

Horizontal Coal Biomass Thermal Oil Boiler

- Capacity:200kw-21000kw 200,000kcal-18,000,000kcal

- Fuel:Coal, charcoal, wood biomass, liquid oil & gas, electric

- Heating Oil Temp.:100°C-320°C

- Combustion Stoker:Chain grate, fixed grate, reciprocating grate

- Yuanda Products:Steam boiler, hot water boiler, thermal oil boiler, hot air furnace

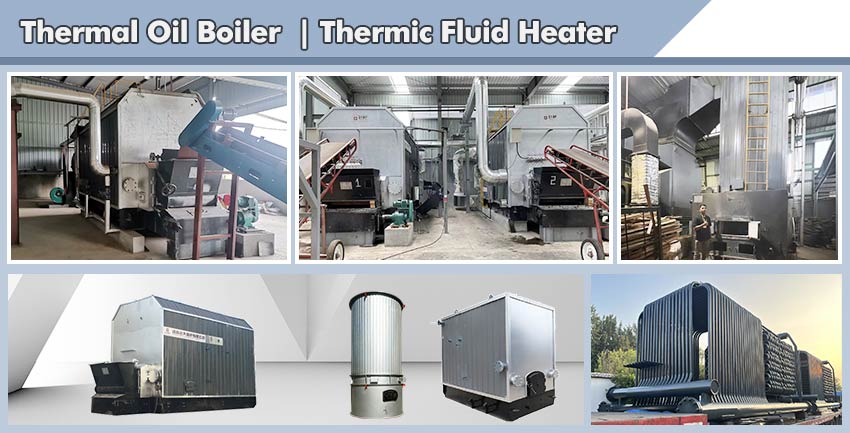

Product Wood/Biomass Thermal Oil Boiler

YLW/YWW/YGW Coal / Biomass Thermal Oil Boiler is a horizontal thermal oil heating system designed for large-capacity and high-temperature industrial applications. Adopts a Chain Grate or Reciprocating Grate or Fixed Grate combustion system, ensuring stable combustion, high thermal efficiency, and reliable long-term operation.

Horizontal three-pass coil structure

Customized manual or automatic fuel feeding

High-quality steel coils with excellent heat transfer

PLC or semi-automatic control system available

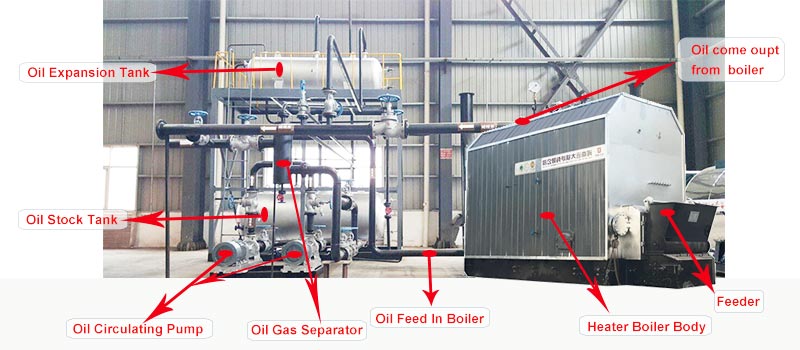

Question: How boiler heating oil circulately ?

1. Feeding tansfer oil into boiler through oil-gas seperator powered by oil-pump.

2. Full-oil boiler, cold oil will stay forced circulating for 6-8Hours, sametime exhaust the gas in oil.

3. Then running thermal oil boiler, deliver the heat between heating equipment and boiler. It can obtain a high operating temperature at low pressure and can do high-precision control on the medium.

Boiler Characteristics:

1. Reach high temperature, boiler operation under low pressure, in stable heating and precise temperature control

2. 100% safety, equipped with perfect device for operation and safety test. Alarm for over-temperature, for low flow

3. Multi-loop coil design for thermal oil boiler inner structure, countercurrent heat transfer process of thermal fluid oil

4. Energy saving, set up air preheater, waste heat boiler, reuse heat of thermal oil, make a higher thermal efficiency

5. New furnace arch with upside down "α" flue gas flow, advanced and scientific fabric technology, improve burning effect

6. Thermal oil boiler, widely used for Textile industry, Food industry, Asphalt production, Plywood factory, Cardboard factory, Rubber industry, Paper industry, Wood industry, Machinery industry, Building materials industry, Synthetic fiber industry, etc.

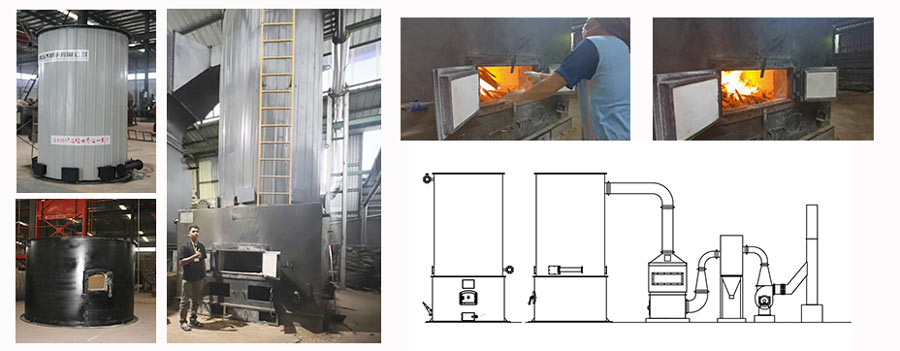

Related Vertical Thermal Oil Boiler

YGL Vertical thermal oil boiler, reducing occupy area, heating oil temperature up to 100°C-320°C at low pressure, hot oil circulating from boiler to tank to equipment use.

- Less occupied area, saving space

- Manual feeding (labor-working)

- Easy Operation

Packaging & Delivery:

Related Thermal Oil Heater

Customized design: vertical type, horizontal type, portable type, skid type, containeried type

Our Boiler Strict Quality Control

1. All materials should be inspected before prodcution and each steel have its ID code which can trace its quality test.

2. 100% Non-Destructive Inspection report of steel plate tube & welding rod.

3. Hydraulic test: make sure strength and tightness of pressure parts.

4. Third part inspection report: By China Henan Boiler Inspection Institute.

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

About us Yuanda Boiler

1. All products Certified With ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

2. Our company established since 1956, over 70 years manufactureing experiences, 18 Years export experience.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 135 countries all over the world, trustable quality & services for lifespan.

| Model | Rated power(MW) | Rated pressure (Mpa) | Thermal oil temperature(℃) | Thermal efficiency(%) | Thermal oil circulation flow(m³/h) | Fuel comsumption(Kg/h) | max transportation weigh(t) |

|---|---|---|---|---|---|---|---|

| YLW-700 | 0.7 | 0.8/1.0 | 250-320 | >83 | 45.7 | 187 | 16.9 |

| YLW-1400 | 1.4 | 0.8/1.0 | 250-320 | >83 | 87.4 | 373 | 22 |

| YLW-2400 | 2.4 | 0.8/1.0 | 250-320 | >83 | 149.8 | 621.3 | 28.6 |

| YLW-2900 | 2.9 | 0.8/1.0 | 250-320 | >83 | 155 | 756 | 24.2 |

| YLW-4200 | 4.2 | 0.8/1.0 | 250-320 | >83 | 225 | 989.3 | 30 |

| YLW-5600 | 5.6 | 0.8/1.0 | 250-320 | >83 | 336 | 1196 | 33.6 |

| YLW-7000 | 7 | 0.8/1.0 | 250-320 | >83 | 383.5 | 1657.4 | 18.2 |

| YLW-8400 | 8.4 | 0.8/1.0 | 250-320 | >83 | 536.2 | 1926.2 | 24.3 |

| YLW-10500 | 10.5 | 0.8/1.0 | 250-320 | >83 | 686.6 | 2442.6 | 27.5 |

| YLW-14000 | 14 | 0.8/1.0 | 250-320 | >83 | 869.1 | 3230 | 31 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||

English

English

.png)

.jpg)

.jpg)