Mobile Solid Fuel Heating Boiler

- Thermal Cap.:50kw-7200kw

- Thermal Cap.:180000btu-29000000btu

- Type:Portable, skid tailer or containerised

- Fuel:Biomass pellets,wood pellet,biomass briquette, biomass waste

- Application:Building, Public service space heating, warehouse, greenhouse, big house, farm, etc.

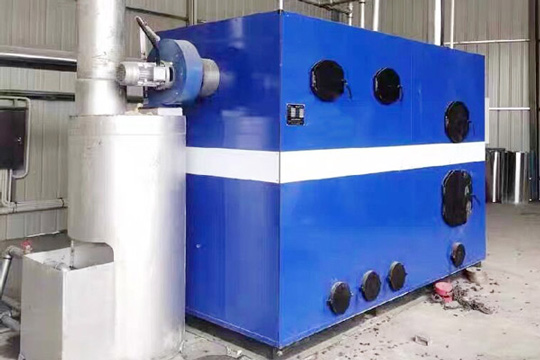

Biomass Heating Plant Containerised Mobile Type Biomass Heating Boiler

Introduction Biomass Heating Plant Boiler 50kw-7200kw

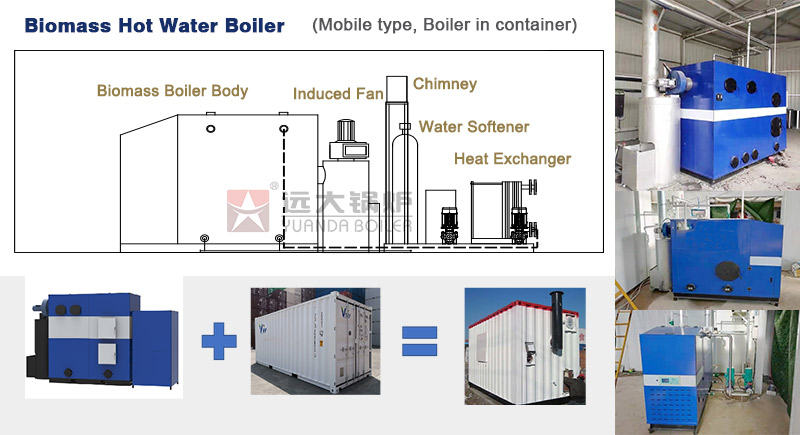

1. Wood biomass combustion heating systems in a container, which is specially prepared for buildings - where there is no enough space for the boiler and fuel room. Heating system customized for any customer needs.

2. Containerised mobile type biomass boiler plants are fully operational biomass heating systems built inside a custom made container with fire-resistant walls. They include a silo, a boiler, the automation and all the electrical works and plumbing already made in the factory. They are easy to install and easy to relocate.

3. Yuanda containerised biomass boiler plants come in different shapes depending on the need of the customer for output and silo capacity.

How to install ? How to use ?

A containerised heating plant is easy to install as it is almost completely manufactured in a factory. Once on the installation site, the boiler plant is set on its concrete pad, the chimney is erected and the heat and electrical networks are connected. Therefore installation is easy and fast and requires only a solid installation pad. The boiler plant is also easy to relocate if needed. Problems due to incorrect cabling is also avoided as everything is mounted and tested before delivery.

Advantages

1. Environmental friendly

All the flue gas cleaning equipment is factory-mounted and can be chosen among different models to meet the local emission regulations.

2. Renewable Biomass Fuel

It is a fuel that was developed to replace coal by a clean renewable fuel in huge coal-fired boilers.

3. Saving Space For Boiler Room

When it's time to heating, where need it, just deliver everywhere. Don't need to prepare boiler room, saving space.

Appearance Special Look

The containerised heating plant can be equipped with additional wooden or metallic cladding to integrate it to its surroundings.

Related Skid tailer type heating boiler

The skid is a metal frame on which the boiler and auxilary equipment are installed. If you wish to purchase a factory-made boiler plant, you can check our containerised biomass heating plants. If you want to install your biomass boiler in a building that already exists or that you plant to build, but wish to benefit from similar time savings during the installation, a skid-mounted biomass boiler is the solution for you.

Depending on the output of the boiler and the need of the customer, the skid can include some part of the ASME piping and all the maintenance platforms needed to operate the boiler. This means that the installation operation can be limited to almost plug-and-play.

For Building Heating Usage

The pellet boiler heats water. The hot water will then circulate in a hydronic system made with insulated pipes and heat exchangers. The heat exchangers will generate hot air that will be pushed in the region of the building that the heat exchanger is installed in. Every heat exchanger has its own thermostat. Therefore, the temperature inside the building can be fine tuned to the customer’s needs.

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

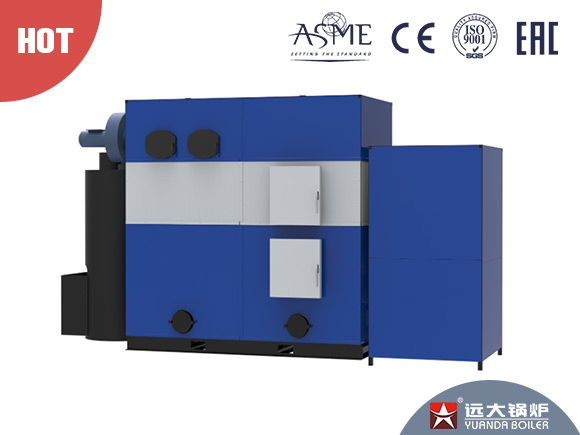

About us Yuanda Boiler

1. All products Certified With ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

2. Our company established since 1956, over 65 years manufactureing experiences, 15 Years export experience.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 103 countries all over the world, trustable quality & services for lifespan.

| Model | CWHS-0.041 | CWHS-0.058 | CWHS-0.088 | CWHS-0.12 | CWHS-0.175 | CWHS-0.24 | CWHS-0.35 | CWHS-0.54 | CWHS-0.7 | CWHS-1.05 | CWHS-1.4 | CWHS-1.75 | CWHS-2.1 | CWHS-2.8 | CWHS-4.2 | CWHS-5.6 | CWHS-7.2 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Working pressure | Atmospheric TYPE | |||||||||||||||||

| Thermal efficiency | 0.93 | |||||||||||||||||

| Reted output (kw) | 41 | 58 | 88 | 120 | 150 | 240 | 350 | 540 | 700 | 1050 | 1400 | 1750 | 2100 | 2800 | 4200 | 5600 | 7200 | |

| Rated out put (×10⁴kcal) | 3.5 | 5 | 7.5 | 10 | 15 | 20 | 30 | 45 | 60 | 90 | 120 | 150 | 180 | 240 | 360 | 480 | 600 | |

| Heating area ㎡ | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4500 | 6000 | 9000 | 12000 | 15000 | 18000 | 24000 | 36000 | 48000 | 60000 | |

| Rated voltage(V) | 220V 380V | |||||||||||||||||

| Induced fan power(W) | 120 | 180 | 250 | 250 | 370 | 550 | 750 | 1100 | 1500 | 2200 | 3000 | 4000 | 7500 | 11000 | 18500 | 18500 | 21000 | |

| Fd fan power(W) | 85 | 120 | 240 | 240 | 320 | 400 | 500 | 550 | 550 | 2200 | 2200 | 3000 | 5500 | 7500 | 11000 | 15000 | 15000 | |

| Chimney Diameter(mm) | 114 | 140 | 165 | 165 | 165 | 165 | 165 | 273 | 273 | 273 | 273 | 325 | 325 | 375 | 700 | 800 | 900 | |

| Circulating water volume(T) | 0.875 | 1.25 | 1.875 | 2.5 | 3.75 | 5 | 7.5 | 11.25 | 15 | 30 | 30 | 37.5 | 45 | 60 | 90 | 120 | 150 | |

| Water inlet and outlet diameter(mm) | 39 | 51 | 51 | 51 | 68 | 68 | 76 | 89 | 89 | 108 | 108 | 140 | 140 | 140 | 180 | 203 | 228 | |

| Dust collector | Φ380×1050 | Φ380×1050 | Φ400×1170 | Φ400×1170 | Φ460×1220 | Φ460×1300 | Φ480×1600 | Φ700×1750 | Φ700×1800 | Φ800×2100 | Φ800×2040 | Φ800×2085 | Φ900×2090 | Φ900×2095 | Φ1000×2180 | Φ1000×2250 | Φ1000×2300 | |

| Fuel consumption(kg/h) | 6.7 | 9.5 | 14 | 19 | 29 | 38 | 57 | 86 | 114 | 171 | 229 | 286 | 343 | 457 | 686 | 914 | 1143 | |

| Boiler size | L(mm) | 1725 | 1780 | 1950 | 1965 | 2135 | 2230 | 2330 | 2735 | 2935 | 3260 | 3110 | 3750 | 4010 | 4340 | 5200 | 5600 | 6300 |

| W(mm) | 700 | 700 | 800 | 763 | 850 | 975 | 1100 | 1170 | 1300 | 1470 | 1560 | 1720 | 1850 | 1980 | 2500 | 2800 | 3250 | |

| H(mm) | 1335 | 1420 | 1370 | 1460 | 1600 | 1890 | 2100 | 2200 | 2400 | 2270 | 2245 | 2535 | 2600 | 2880 | 3380 | 3500 | 3800 | |

| Fuel silo size | L(mm) | Integrated design of boiler and silo | 1250 | 1250 | 1600 | 1600 | 1500 | 1500 | 1700 | 1980 | ||||||||

| W(mm) | 1160 | 1160 | 1200 | 1200 | 1450 | 1450 | 1650 | 1700 | ||||||||||

| H(mm) | 2110 | 2110 | 2330 | 2330 | 2980 | 2980 | 3380 | 3680 | ||||||||||

| Shipping weight(kg) | 350 | 450 | 700 | 850 | 1100 | 1300 | 1800 | 2400 | 3000 | 4000 | 5000 | 5800 | 6800 | 12000 | 15000 | 18000 | 20000 | |

| Note: If any changes should follow the factory technical data. pls contact us to get technical parameter. | ||||||||||||||||||

Chinese

Chinese

English

English

.png)