- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- DHL Water Tube Corner Tube Coal ...

- SHX Circulating Fluidized Bed Co...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Small Solid Fuel Coal Heating Bo...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg HFO Diesel Fired Thermal...

- Solid Fuel Coal Wood Biomass Fir...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- Horizontal Coal Biomass Thermal ...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Vertical Coal Wood Biomass T...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

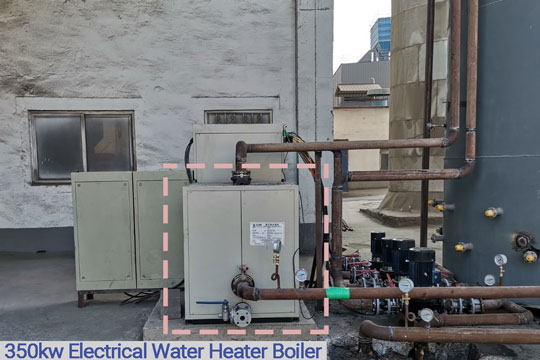

Electric Hot Water Boiler

- Heat Capacity:60kw-7000kw

- Voltage:Customized as required

- Hot Water Temp:60°C-115°C

- Structure:Vertical or Horizontal

- Manufacture Standard:GB, ISO, CE, ASME, DOSH, EAC

Electric Hot Water Boiler

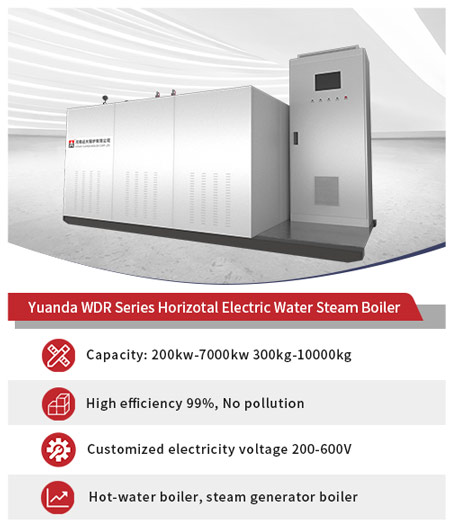

Horizontal Electric Boiler

WDR horizontal electric boiler, it is horizontal type electricity heating tube type boiler. It's kind of new high technology product which takes electricity as energy.

With advantages of environmental protection, no pollution, no noise, convenient installation,small occupation, full automatic control and high thermal efficiency up to 98%.

Vertical Electric Boiler

LDR vertical electric boiler, is small size vertical type electric heated boiler. Simple structure, qiuck startup, one-button start on, small footprint, thermal efficiency reach to 98%.

1) Small size, Light weight, Easy to install, Portable, No pollution.

2) Dual safety guarantee, Electric heating, Safety ensurance.

Why choose electric boiler Advantages

Electric boiler is very popular as no-emission-pollute boiler. Lots of boss consider the invest cost of electric boiler when some factories plan to replace old boiler or increase factory productions scale.

Electric boiler design is kind composed of furnace, water supply, self-control, heating and safety protection system. It uses electricity to generate heat and generate steam with a certain pressure. With advantages of fully-automation (convenient use), no pollution, simple install easy-operation, high-efficiency, new modern deisgn, portable to move. Somewhere electricity cost is cheap in the local, it will be a great choice to get electric boiler.

Calcaulate Consumption

Generally, 700kw electric boiler consumps 700 kw, in addition, auxiliary power consumption in 50kw-100kw roughly.

Remark: If you need consumption cost analysis, contact shirley@yuanda-boiler.com

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

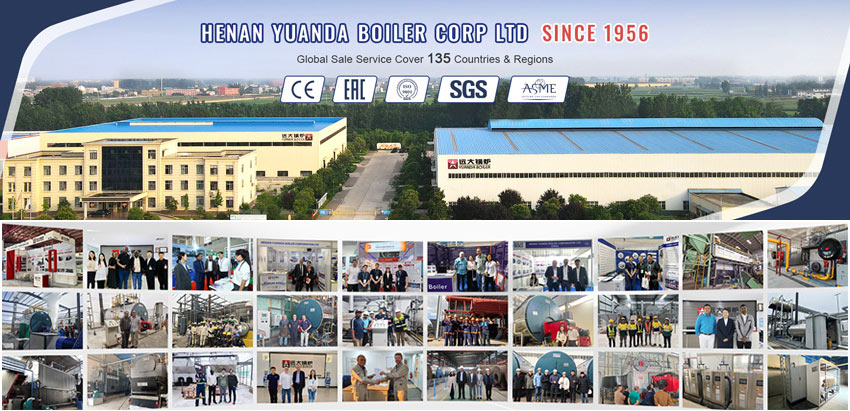

About us Yuanda Boiler

1. All products Certified With ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

2. Our company established since 1956, over 70 years manufactureing experiences, 18 Years export experience.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 135 countries all over the world, trustable quality & services for lifespan.

| Electric Heating Water Boiler Technical Parameter Data | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | LDR0.06 | LDR0.09 | LDR0.12 | LDR0.18 | LDR0.24 | LDR0.36 | LDR0.48 | LDR0.54 | |

| Rated working pressure | MPa | 0.3/0.5/0.7 | |||||||

| Staturated water temperature | ℃ | 95/70 | |||||||

| Input power | KW | 60 | 90 | 120 | 180 | 240 | 360 | 480 | 540 |

| Input current | A | 90 | 135 | 180 | 270 | 360 | 540 | 720 | 810 |

| Rated voltage | V | 220/380 (customized) | |||||||

| Power×Group | KW×P | 15×4 | 15×6 | 15×8 | 25×6+15×2 | 25×9+15 | 36×10 | 36×12+25×2 | 36×15 |

| Diameter water outlet | DN | 50 | 50 | 50 | 50 | 50 | 80 | 80 | 80 |

| Diameter water return | DN | 50 | 50 | 50 | 50 | 50 | 80 | 80 | 80 |

| Diameter water inlet | DN | 15 | 15 | 15 | 15 | 15 | 25 | 25 | 25 |

| Diameter blowoff valve | DN | 25 | 25 | 25 | 40 | 40 | 40 | 40 | 40 |

| Diameter safety valve | DN | 15 | 15 | 15 | 25 | 25 | 40 | 40 | 40 |

| Overall size | L mm | 750 | 750 | 750 | 1200 | 1200 | 1600 | 1600 | 1600 |

| W mm | 650 | 650 | 650 | 1100 | 1100 | 1200 | 1350 | 1350 | |

| H mm | 1380 | 1380 | 1380 | 1900 | 1900 | 2000 | 2200 | 2200 | |

| Weight | kg | 180 | 200 | 235 | 485 | 525 | 620 | 710 | 820/1350 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

English

English

.png)

.jpg)