- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- DHL Water Tube Corner Tube Coal ...

- SHX Circulating Fluidized Bed Co...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Small Solid Fuel Coal Heating Bo...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg HFO Diesel Fired Thermal...

- Solid Fuel Coal Wood Biomass Fir...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- Horizontal Coal Biomass Thermal ...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Vertical Coal Wood Biomass T...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

.jpg)

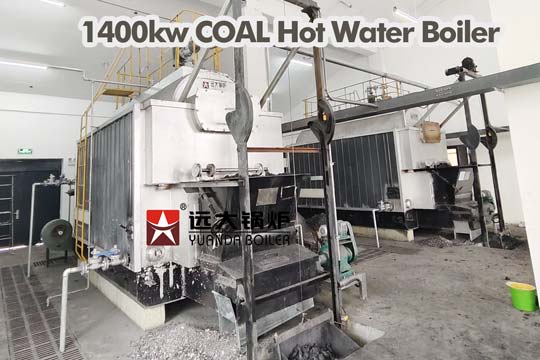

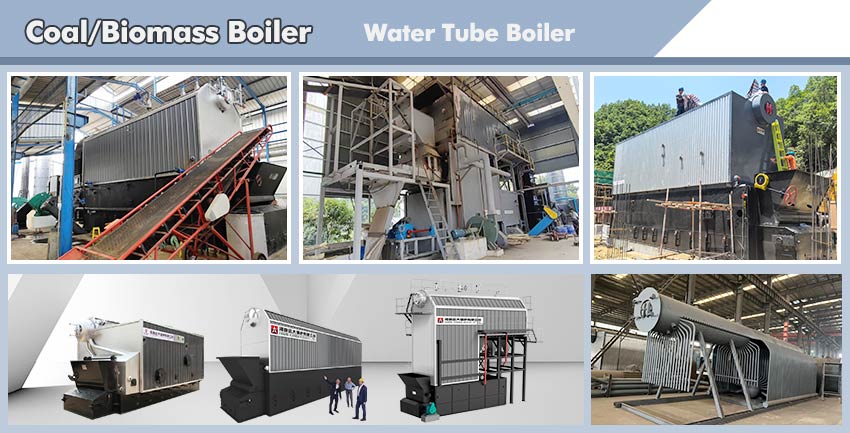

Industrial Coal Fired Boiler Solid Fuel Charcoal Biomass Boiler Steam Boiler Hot Water Heater Thermal Oil Boiler

- Our Products:Coal Steam Boiler, Coal Hot Water Boiler, Coal Thermal Oil Boiler, CFB Coal Boiler

- Capacity:0.1ton-80ton, 70kw-28000kw

- Fuel:Coal, charcoal, briquette, wood, biomass, pellets, jute waste...

- Pressure:1bar-38bar 0.1mpa-3.8mpa

- Manufacture Standard:GB ISO CE ASME DOSH EAC

Yuanda Industrial Coal Boiler

We supply Coal steam boiler, Coal hot water boiler, Coal thermal oil boiler.

.jpg)

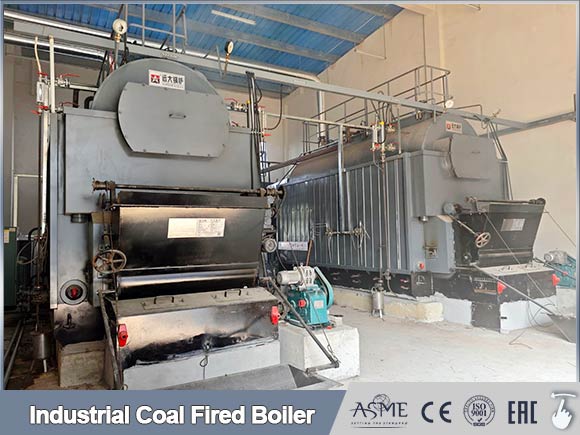

Hot Selling DZL Coal Boiler

DZL series chain grate coal boiler, it is horizontal three-pass water-tube & fire-tube boiler. DZL use chain grate combustion stoker for coal combustion efficiently, automatically.

1. It could burn coal, charcoal, briquette, biomass, wood, ricehusk, palm shells

2. Water-tube and fire tube use spairally corrugated tubes, enhance heat transferring

3. Furnace arch with upside down "α" flue gas flow, make coal/biomass burning sufficiently

4. Set steam-water separaing equipment, has high-quality & sufficient steam output

.jpg)

Advantages DZ Series Coal Boiler

1. Easy Installation: Fast-assembly leave from factory, easy to transport and install at site.

2. Full Combustion: Reasonable design of furnace structure with best suitable grate device, fuel fired fully.

3. High Efficiency Grate: Chain grate, easy operation, have lots of advantages compared to traditional grate.

4. High Security: Equip with water lack protection and over pressure protection devices, security and reliable.

5. Long Life and Durable: Advanced production processes, strict quality inspection, boiler life span above 20 years.

6. Environmental Protection and Low Noise: Low noise fans, dust remove device, meet local emission requirements.

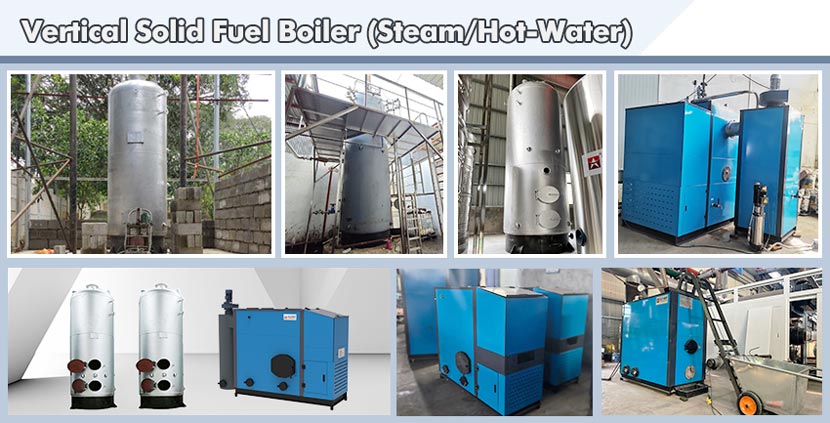

Product Vertical coal boiler

Small capacity vertical coal boiler, small steam boiler, small hot water boiler.

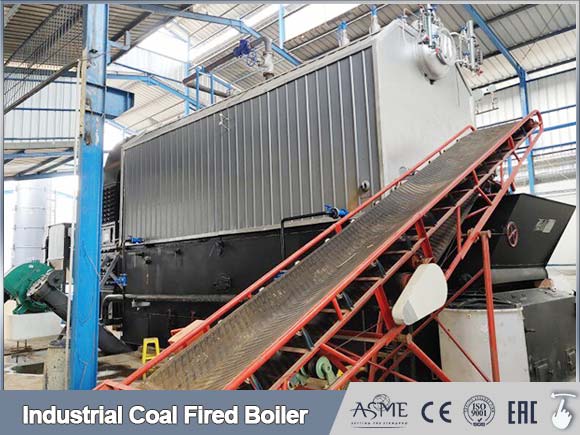

Product Water Tube Boiler

SZL Chain grate coal boiler, double drums A or D type layout, water membrane wall design, large furnace water tube boiler.

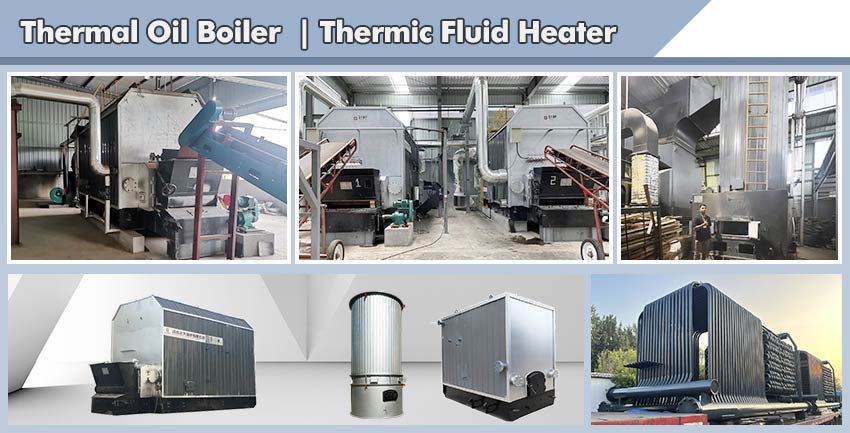

Product Coal Thermal Oil Boiler

Thermal Oil Heater Boiler, use in textile, bitumen, plywood, asphalt, plastics, foods, heating tanks, heating crude oil, oil refinery.....

Boiler Quality Control Strictly

1. All materials should be inspected before prodcution and each steel have its ID code which can trace its quality test.

2. 100% Non-Destructive Inspection report of steel plate tube & welding rod.

3. Hydraulic test: make sure strength and tightness of pressure parts.

4. Third part inspection report: By China Henan Boiler Inspection Institute.

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

About us Yuanda Boiler

1. Our company established since 1956, over 70 years manufactureing experiences, 18 Years export experience.

2. Qualified by ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 135 countries all over the world, trustable quality & services for lifespan.

| DZ Series Steam Boiler Technical Parameter Table | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Rated capacity(t/h) | Rated pressure (Mpa) | Rated steam temperature(℃) | feed temperature(℃) | Thermal efficiency(%) | Boiler water volume(m³) | Exhaust temperation(℃) | Fuel comsumption(Kg/h) | max transportation weigh(t) |

| DZH1 | 1 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 3.15 | 127.25 | 192.32 | 9 |

| DZL1 | 1 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 3.15 | 113.34 | 190.42 | 13.5 |

| DZH2 | 2 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 4.75 | 126.41 | 386.47 | 15 |

| DZL2 | 2 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 4.77 | 106.34 | 393.77 | 22 |

| DZH4 | 4 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 7.7 | 137.25 | 782.29 | 18.5 |

| DZL4 | 4 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 8.2 | 124.49 | 756.89 | 27.6 |

| DZH6 | 6 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 7.4 | 146.83 | 1169.57 | 25 |

| DZL6 | 6 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 8.1 | 137.29 | 1148.68 | 35 |

| DZL8 | 8 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 9.6 | 141.06 | 1602.44 | 38 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

English

English

.png)