- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- DHL Water Tube Corner Tube Coal ...

- SHX Circulating Fluidized Bed Co...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Small Solid Fuel Coal Heating Bo...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg HFO Diesel Fired Thermal...

- Solid Fuel Coal Wood Biomass Fir...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- Horizontal Coal Biomass Thermal ...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Vertical Coal Wood Biomass T...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

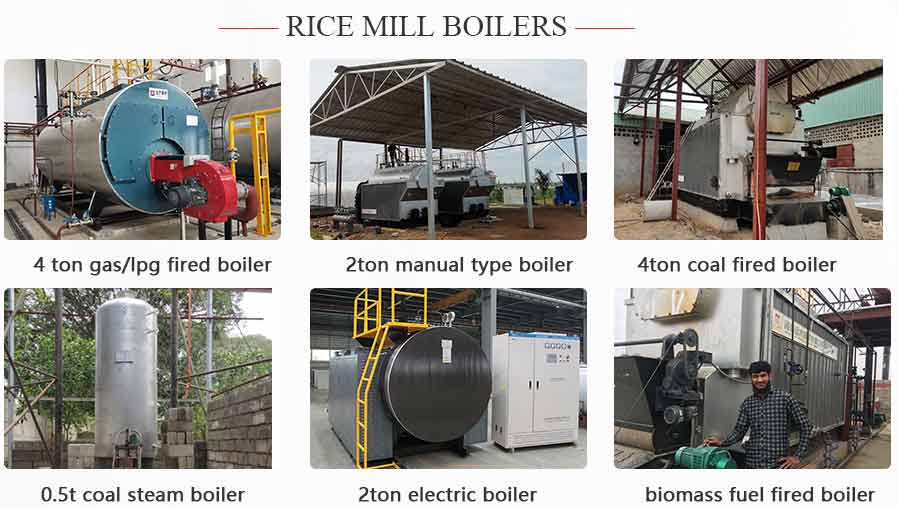

Choose a suitable steam boiler for rice mill

Introduction:

Steam boiler work in the process of parboiling and drying in rice mill, our boiler could satisfy a rice mill production in 15-300ton/day.

Our steam boilers have been widely used in rice mill worldwide, such as Nigeria Myanmar Bangladesh Pakistan Nepal Uganda......

Remark: In pictures, it's 4ton husk fired steam boiler in Nigeria, for parboiling rice 100T/D, boilers and dryers for rice mills.

.jpg)

Need boiler for rice mill, send details as following:

① pls tell your required boiler capacity in your factory; if not devide, pls tell your parboiling rice production capacity per day.

② choose power from gas/oil/lpg/coal/biomass/husk/electricity, according your local situation, choose the best energy-saving

③ If you have other special requirments, pls send us by shirley@yuanda-boiler.com

Our Service

1. Pre-sale service:

Engineer support to provide relative technical data for client choosing equipments, cost analysis and foundation drawing, layout drawing, boiler room layout, etc;Provide boiler running site for your visit.

2. In-sale service:

A full range of original spare parts are available for Yuanda boiler. Keep 24 hours online and close contacts during the process with packaging/shipping pictures.

3. After-sale service:

Engineers on-site guidance installation and commissioning, free training for boiler operater, free maintenance and repair and lifelong service.

.jpg)

English

English

.png)