- Home

- Products

Wood Biomass Boiler

Wood Biomass Boiler

- Wood Coal Sawdust Ricehusk Bagas...

- Vertical Biomass Wood Boiler Wat...

- SZL SZW Series Water Tube Coal B...

- BFB CFB Fluidized Bed Boiler

- Woodchips log pellet sawdust Woo...

- Biomass Burner Wood Pellet Riceh...

- SZW Reciprocating Grate Stoker B...

- DHW DHG Corner Tube Water Tube B...

- Biomass Pellets Wood Pellets Ste...

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- Small Solid Fuel Coal Heating Bo...

- DHL Water Tube Corner Tube Coal ...

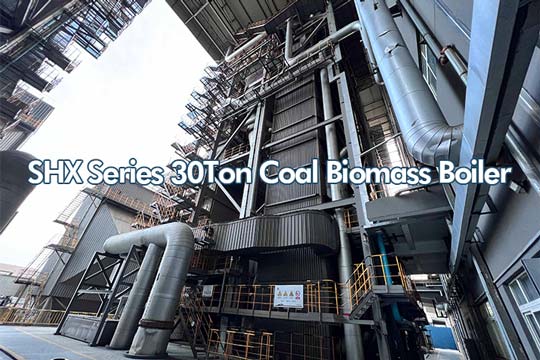

- SHX/DHX Series Circulating Fluid...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg Diesel Fired Thermal Oil...

- Solid Fuel Coal Wood Biomass The...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- YLW Series Horizontal Coal Therm...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Seires Vertical Wood Biomass...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

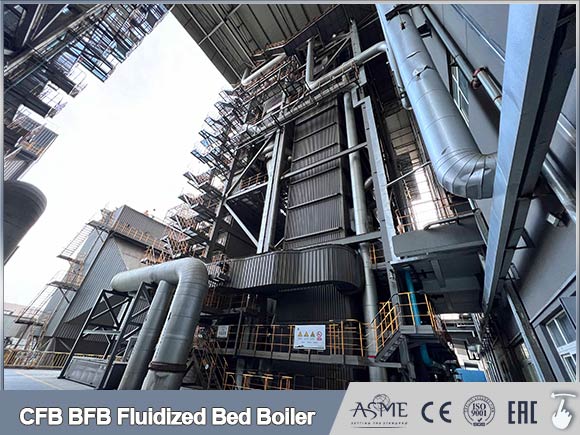

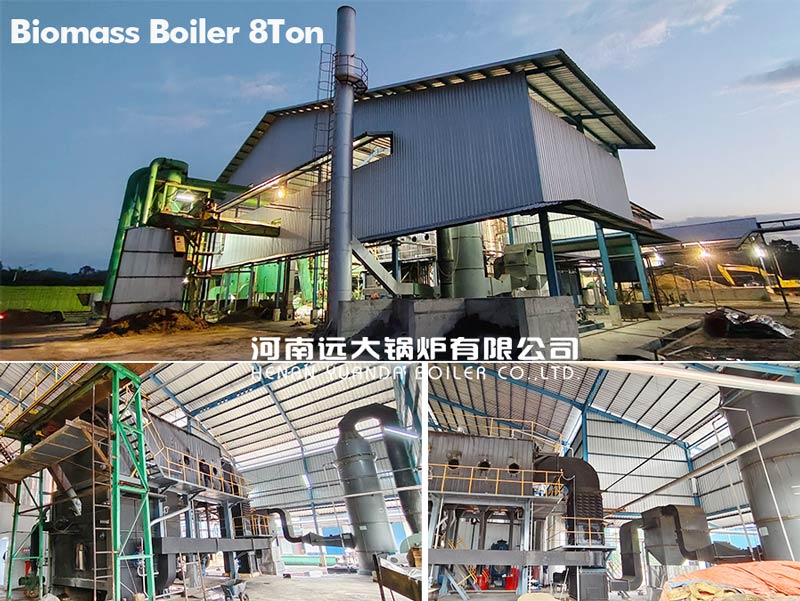

BFB CFB Fluidized Bed Boiler

- Capacity:4ton-75ton

- Biomass Fuel:Wood, sawdust, palm kernel shells/fibre, coconut shells, bagasse, ricehusk, bark, dried sewage sludge/poultry litter

- High Thermal Efficiency:Over 88%

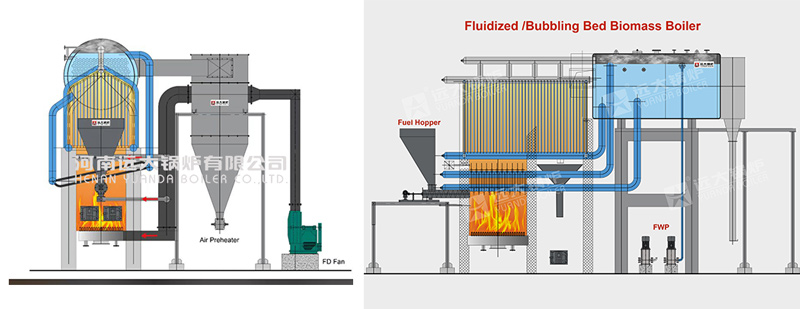

- Fluidization Design:Air is blown upward through a bed of inert material at a velocity that suspends the particles, creating a bubbling fluid-like state.

Bubbing Fluid Bed Boiler 4Ton-75Ton

Bubbling Fluidized Bed Boiler is a type of coal biomass boiler using fluidized bed combustion system, design suitable boiler according to per customer's need.

Fluidization: Air is blown upward through a bed of inert material (e.g., sand or ash) at a velocity that suspends the particles, creating a bubbling fluid-like state.

Combustion: Biomass fuel (e.g., wood chips, agricultural waste, pellets) is injected into the bed. The turbulent mixing of fuel and bed material ensures efficient heat transfer and combustion at lower temperatures (typically 800°C–900°C).

Heat Recovery: Flue gases heat recovery.

Biomass Fuel Compatibility

Suitable Fuels:

(1) Wood chips, sawdust, bark.

(2) Agricultural residues (palm kernel shells/fibre, straw, rice husk, coconut shells).

(3) Energy crops (miscanthus, switchgrass).

(4) Dried sewage sludge or poultry litter.

Fuel Requirements:

(1) Moisture content: <50% (preferably <30% for optimal efficiency).

(2) Particle size: <50 mm (may require shredding/chipping).

Advantages Bubbing Bed Boiler

1. High Combustion Efficiency: Excellent fuel-air mixing and low combustion temperatures improve efficiency (up to 97%).

2. Fuel Flexibility: Can burn diverse biomass fuels (e.g., wet, high-ash, or irregularly shaped feedstocks).

3. Low Emissions:

(1) Reduced NOx (due to lower combustion temps).

(2) Reduced SOx (if limestone is added to the bed to capture sulfur).

4. Ash Management: Less risk of ash melting (slagging) compared to fixed-bed boilers.

Boiler System Components:

1. Combustion Chamber: Where the fluidized bed and combustion occur.

2. Air Distribution System: Nozzles or grids to supply primary (fluidizing) and secondary (combustion) air.

3. Fuel Feeding System: Screw conveyors or pneumatic systems to inject biomass into the bed.

4. Heat Exchanger: Tubes/coils to transfer heat from flue gases to water/steam.

5. Ash Handling System: Removes ash and bed material for disposal or reuse.

6. Emissions Control: Cyclones, bag filters, or scrubbers to reduce particulate matter and pollutants.

Boiler Quality Control Strictly

1. All materials should be inspected before prodcution and each steel have its ID code which can trace its quality test.

2. 100% Non-Destructive Inspection report of steel plate tube & welding rod.

3. Hydraulic test: make sure strength and tightness of pressure parts.

4. Third part inspection report: By China Henan Boiler Inspection Institute.

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

About us Yuanda Boiler

1. Our company established since 1956, over 65 years manufactureing experiences, 15 Years export experience.

2. Qualified by ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 132 countries all over the world, trustable quality & services for lifespan.

| BFB Bubbling Fluidized Bed Steam Boiler Parameters | |||||

|---|---|---|---|---|---|

| Model | Capacity (ton/h) | Working Pressure | Steam Temperature | Input Water Temp. | Factory mode |

| BFB4 | 4 | 1.25Mpa-3.82Mpa | 194℃-450℃ | 105℃-112℃ | Field Assembly |

| BFB6 | 15 | ||||

| BFB8 | 20 | ||||

| BFB10 | 25 | ||||

| BFB15 | 30 | ||||

| BFB20 | 35 | ||||

| BFB25 | 40 | ||||

| BFB30 | 45 | ||||

| BFB40 | 50 | ||||

| BFB50 | 55 | ||||

| SHX60 | 60 | ||||

| SHX65 | 65 | ||||

| SHX70 | 70 | ||||

| SHX75 | 75 | ||||

English

English

.png)