- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- DHL Water Tube Corner Tube Coal ...

- SHX Circulating Fluidized Bed Co...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Small Solid Fuel Coal Heating Bo...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg HFO Diesel Fired Thermal...

- Solid Fuel Coal Wood Biomass Fir...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- Horizontal Coal Biomass Thermal ...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Vertical Coal Wood Biomass T...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

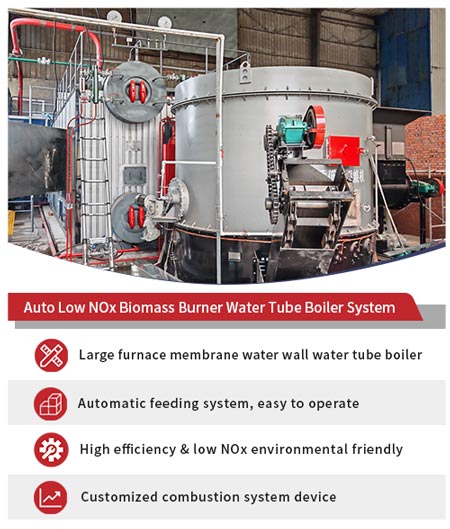

Biomass Wood Sawdust Burner Hot Water Boiler

- Capacity:300kw-14000kw

- Heat Temperature:60°C-130°C

- Fuel:Biomass, wood chips, sawdust, pellets, ricehusk

- Application:For central heating, factory heat processing

- Brief Intro:Fire tube boiler, adopts biomass burner combustion device, work automatically

Biomass Burner Boiler

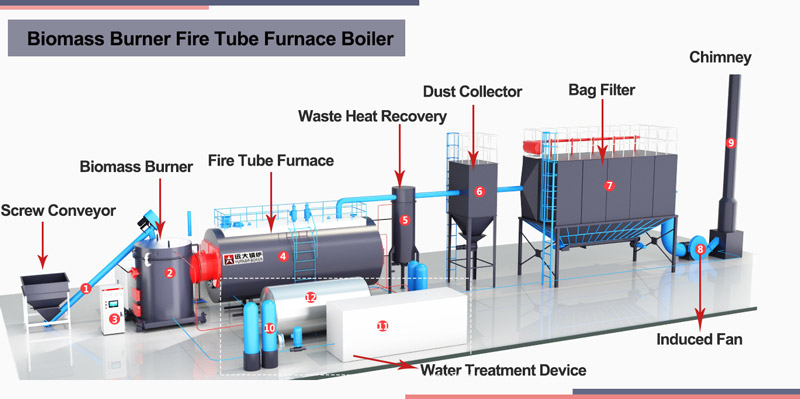

Biomass Fire Tube Boiler With Burner

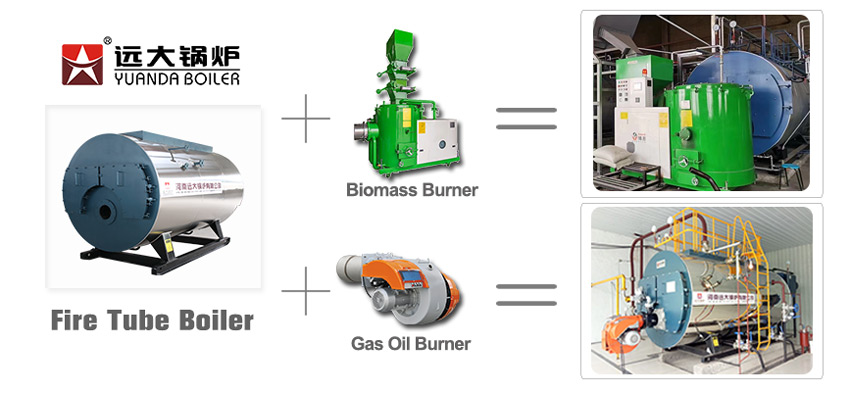

Combined Biomass Boiler:

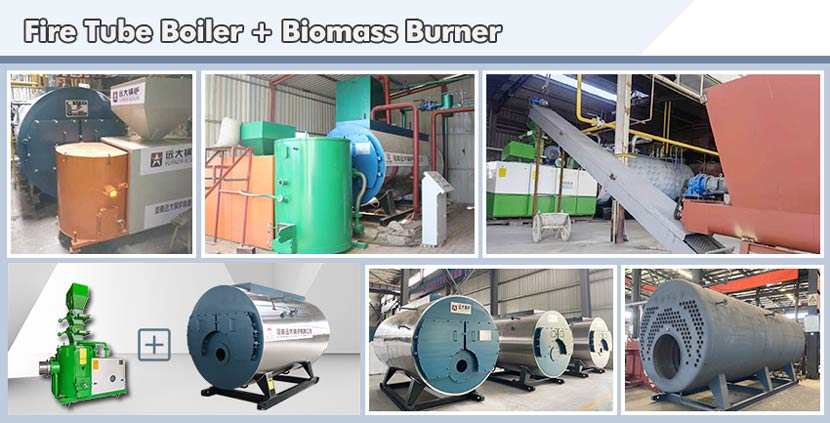

1. Biomass burner + Fire tube boiler

2. Biomass burner + water tube boiler

Once you don't want to use biomass, buy gas/oil burner to replace the biomass burner, it becomes gas/oil fired boiler.

Biomass Burner Boiler, husk/pellets fuel is sent into boiler combustion chamber by feeder, fuel combustion process is like to gas/oil burning automatically in boiler; Our WNS model boiler work with biomass burner, could achieve higher heat efficiency up to 90% comparing with normal biomass burning directly boiler. If you have interest, inquire to know more by shirley@yuanda-boiler.com

Biomass Burner Boiler Features

1. The biomass burning boiler Integrated the advantages of chain type biomass boiler and gas boiler.It is biomass fuel boiler of low cost, energy conservation, environmental protection and thermal efficiency can reach above 90%.

2. Installation is simple, maintenance is convenient.

3. The structure of three return, threaded pipe technology and the characteristics of the wet back structure, increase the heating area. improve the efficiency of the boiler.

Boiler Advantages

1. Low carbon and environmental protection: low carbon emission, renewable fuel, low nitrogen oxide emission, no sulfur emission.

2. Gasification combustion: segmented combustion, low temperature combustion in the furnace, and secondary high temperature combustion at the burner.

3. Various fuels: it can burn biomass wood chips, wood blocks, briquette, biomass pellets and other fuels.

4. Wide range of applications: boilers, drying, hot blast stoves, kilns, annealing furnaces, incinerators, aluminum bar heating furnaces, etc.

5. High efficiency and energy saving: Compared with natural gas, it saves more than 50% energy, and it saves about 30% compared with biomass pellet fuel.

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

About us Yuanda Boiler

1. All products Certified With ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

2. Our company established since 1956, over 70 years manufactureing experiences, 15 Years export experience.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 135 countries all over the world, trustable quality & services for lifespan.

| Biomass Fire Tube Boiler Technical Parameter Data | |||||||

|---|---|---|---|---|---|---|---|

| Model | Rated power(KW) | Rated pressure (Mpa) | Rated output temperature(℃) | Rated return water temperature(℃) | Thermal efficiency(%) | Pellets Consum (kg/hr) | max transportation weigh(t) |

| WNS0.35 | 350 | 0/0.7/1.0/1.25 | 95/115/130℃ | 70℃ | >92% | 75 | 2.65 |

| WNS0.7 | 700 | 150 | 4.66 | ||||

| WNS1.4 | 1400 | 300 | 6.53 | ||||

| WNS2.1 | 2100 | 450 | 7.3 | ||||

| WNS2.8 | 2800 | 600 | 8.1 | ||||

| WNS4.2 | 4200 | 900 | 15.1 | ||||

| WNS5.6 | 5600 | 1200 | 18.2 | ||||

| WNS7.0 | 7000.0 | 1500 | 25.6 | ||||

| WNS10.5 | 1050 | 2250 | 29.1 | ||||

| WNS14.0 | 1400.0 | 3000 | 47.8 | ||||

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||

English

English

.png)