- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- DHL Water Tube Corner Tube Coal ...

- SHX Circulating Fluidized Bed Co...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Small Solid Fuel Coal Heating Bo...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg HFO Diesel Fired Thermal...

- Solid Fuel Coal Wood Biomass Fir...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- Horizontal Coal Biomass Thermal ...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Vertical Coal Wood Biomass T...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

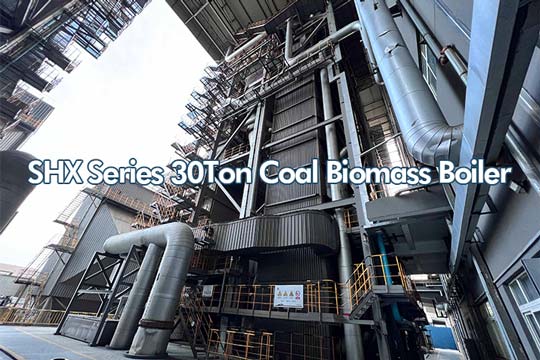

SHX Circulating Fluidized Bed Coal Fired Boiler

- Products:4ton-75ton

- Fuel:Coal, Biomass, Bagasse, Sludge, Solid Waste

- Pressure:1.0Mpa-2.5Mpa

- Working Temperature:Steam 194℃-400℃ Hotwater70℃-130℃

- Manufacture Standard:GB ISO CE ASME DOSH EAC

Circulating Fluid Bed Boiler #SteamBoiler #HotWaterBoiler

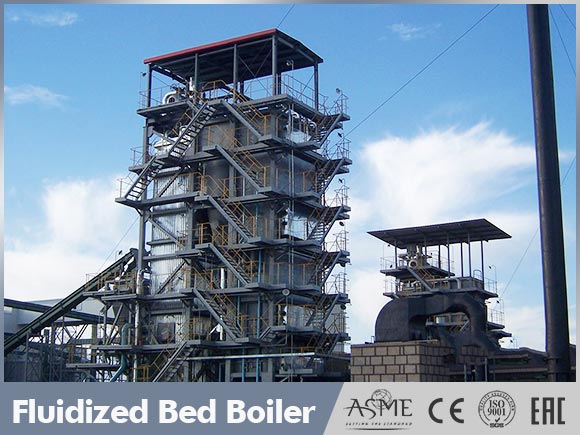

Circulating fluidized bed combustion technology, is kind of new and mature coal combustion clean technology, with high-efficiency, low-pollution.

With characteristic of low-temperature combustion, the NOx emissions are much lower than that of normal pulverized coal furnaces. CFB Boiler has NOx emission only about 100mg/Nm3, and can achieve direct desulfurization during the combustion process, with high desulfurization efficiency. The technical equipment is economical and simple, and its initial investment and operating costs for desulfurization are much lower than that of dry pulverized coal furnace plus flue gas desulfurization (PC+FCD).

SHX & DHX Series Boiler

SHX series circulating fluidized bed boiler, double drum horizontal type boiler.

DHX series circulating fluidized bed boiler, single drum horizontal type boiler.

1. It has wide fuel adaptability and high combustion efficiency, especially suitable for low calorific value and low-quality COAL/BIOMASS, Sludge, Solid Waste.

2. The discharged ash has good activity and is easy to be comprehensively utilized without secondary ash pollution.

3. The load adjustment range is large, and the low load can be reduced to about 30% of the full load.

Advantages CFB Coal Boiler

Low coal consumption: high-efficiency separation + circulating combustion, combustion efficiency >99% or more, thermal efficiency >92%, coal consumption reduced by more than 3%

Save electricity bills: Restructure the flow pattern to achieve low bed pressure operation. The low power consumption rate of the factory can save more than 20% of the fan power consumption.

Environmental protection and low emissions: precise low-temperature staged combustion and air distribution, ultra-low initial emissions of SO2 and NOx, and superior environmental performance

Low wear: low bed pressure operation, low flue gas flow rate, nearly zero wear on the heating surface, low maintenance rate, annual operating time >8000 hours

Good fluidization: Patented improved bell-type wind cap solves the problems of ash pouring and fluidization to ensure boiler combustion efficiency and low emissions

High separation: The optimized center-offset high-efficiency cyclone separator is used to ensure efficient separation, with an efficiency of over 99.6

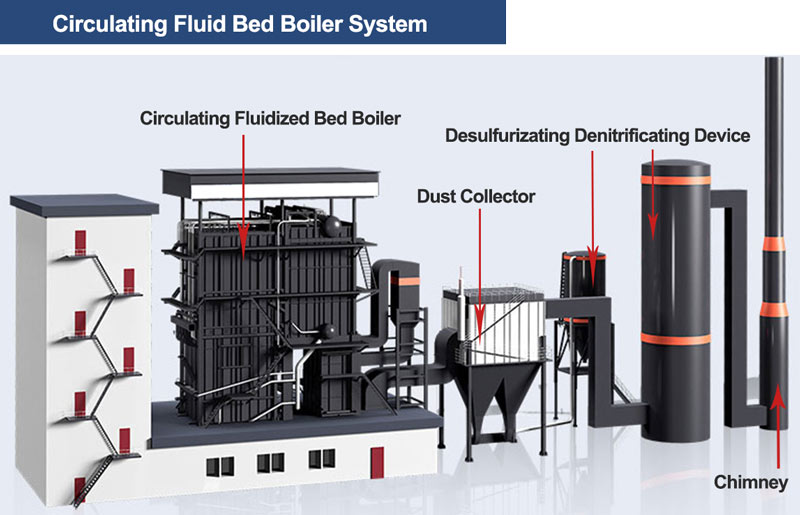

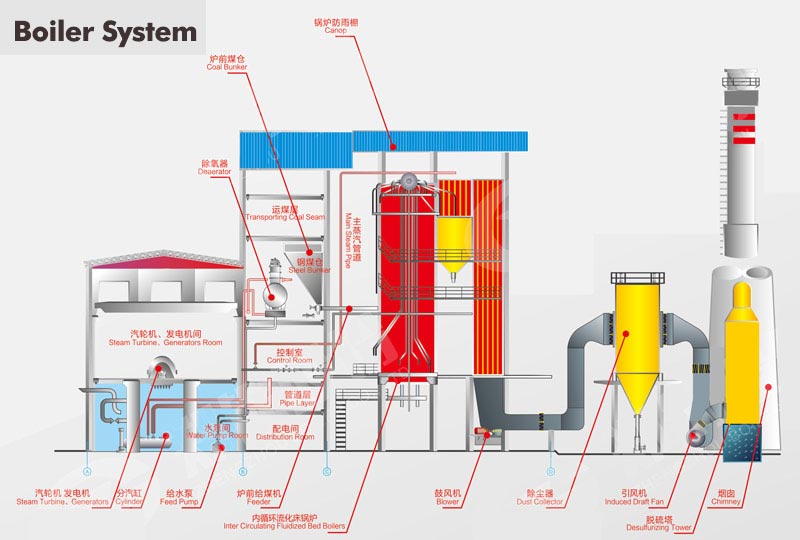

Auxiliary system CFB Coal Boiler

1. Softened water supply system: soft water, demineralized water system, deaerator, water supply pump, water tank ammonia adding device, dosing device

2. Steam (hot water) system: steam (water) cylinder, temperature reducing and pressure reducing device

3. Fuel supply and preparation system: coal loader, belt conveyor, crusher, vibrating screen, electronic belt scale, electromagnetic iron remover, double pear unloader, furnace front coal feeder, etc.

4. Smoke and air system: blower, induced draft fan, chimney, etc.

5. Sewage (steam) system: continuous exhaust, fixed exhaust, sampler, silencer

6. Electronic control system: ordinary control, PLC control, DCS control

7. Flue gas purification system: dust collector, desulfurization device, denitrification device, pneumatic ash conveyor (ash silo), etc.

8. Slag discharging system: slag discharging machine, slag conveying belt, (slag bin), etc., other equipment in the boiler room; heat exchanger or power generation equipment

Boiler Quality Control Strictly

1. All materials should be inspected before prodcution and each steel have its ID code which can trace its quality test.

2. 100% Non-Destructive Inspection report of steel plate tube & welding rod.

3. Hydraulic test: make sure strength and tightness of pressure parts.

4. Third part inspection report: By China Henan Boiler Inspection Institute.

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

About us Yuanda Boiler

1. Our company established since 1956, over 65 years manufactureing experiences, 15 Years export experience.

2. Qualified by ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 132 countries all over the world, trustable quality & services for lifespan.

| SHX Series Circulating Fluidized Bed Steam Boiler Parameters | |||||

|---|---|---|---|---|---|

| Model | Capacity (ton/h) | Working Pressure | Steam Temperature | Input Water Temp. | Factory mode |

| SHX10 | 10 | 1.25Mpa-3.82Mpa | 194℃-450℃ | 105℃-112℃ | Field Assembly |

| SHX15 | 15 | ||||

| SHX20 | 20 | ||||

| SHX25 | 25 | ||||

| SHX30 | 30 | ||||

| SHX35 | 35 | ||||

| SHX40 | 40 | ||||

| SHX45 | 45 | ||||

| SHX50 | 50 | ||||

| SHX55 | 55 | ||||

| SHX60 | 60 | ||||

| SHX65 | 65 | ||||

| SHX70 | 70 | ||||

| SHX75 | 75 | ||||

English

English

.png)