- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- DHL Water Tube Corner Tube Coal ...

- SHX Circulating Fluidized Bed Co...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Small Solid Fuel Coal Heating Bo...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg HFO Diesel Fired Thermal...

- Solid Fuel Coal Wood Biomass Fir...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- Horizontal Coal Biomass Thermal ...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Vertical Coal Wood Biomass T...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

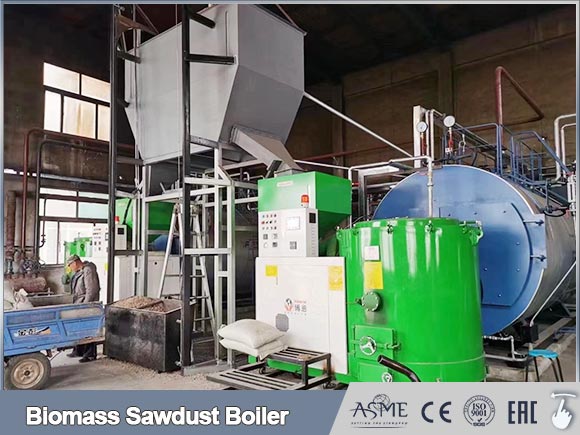

Biomass Sawdust Boiler

- Capacity:0.5ton-20ton, 350kw-14000kw

- Fuel:Sawdust biomass wood ricehusk solidwaste

- Heat Temperature:60°C-200°C

- Our Products:Steam boiler, hot water boiler, thermal oil boiler

- Manufacture Standard:GB, CE, ASME, DOSH, EAC

Sawdust Fired Boiler

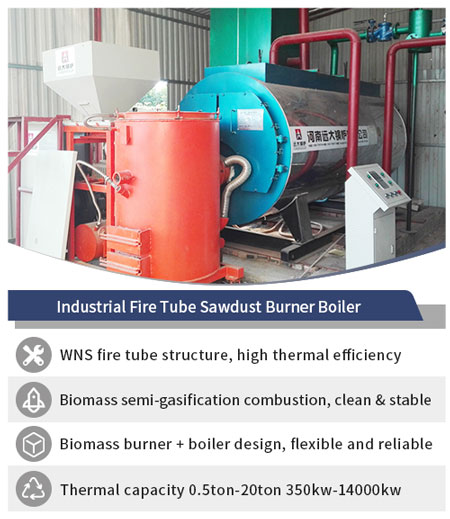

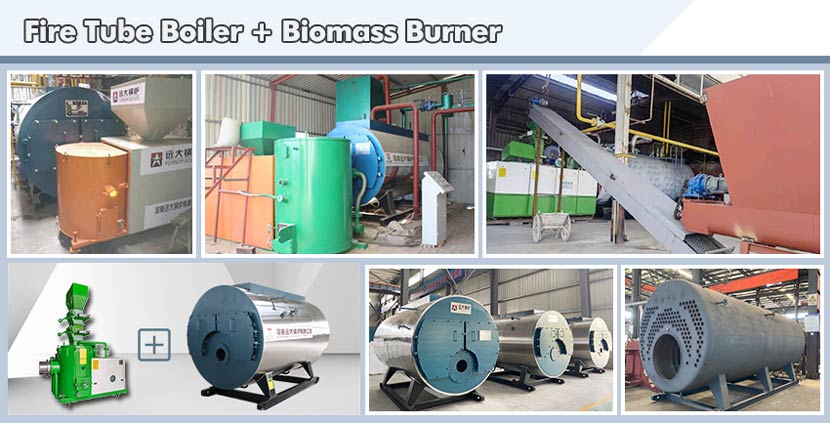

Sawdust Boiler + Biomass Burner

WNS fire tube sawdust burner boiler, integrates biomass semi-gasification burner with three-pass fire tube boiler structure.

High-efficiency fire tube boiler combining biomass semi-gasification combustion with stable and economical steam output.

1. Biomass Semi-Gasification Combustion

The biomass burner adopts semi-gasification technology, enabling thorough fuel burnout, stable flame, and reduced dust and unburned carbon emissions.

2. WNS Three-Pass Fire Tube Structure

Classic WNS fire tube design ensures sufficient heat exchange, long flue gas residence time, and high thermal efficiency.

3.Wide Fuel Adaptability, Stable Operation

Suitable for various biomass fuels such as wood chips, sawdust, rice husk, and other processed biomass, with strong adaptability to fuel moisture and size variations.

4. Automatic Feeding & Control System

Equipped with screw feeder and air blower feeding system, combined with automatic control and safety interlock, ensuring easy operation and low labor cost.

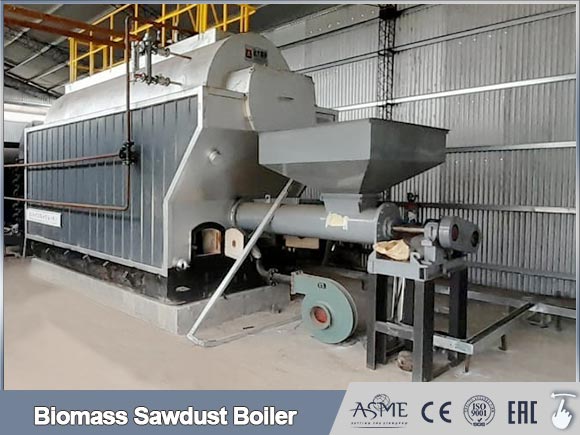

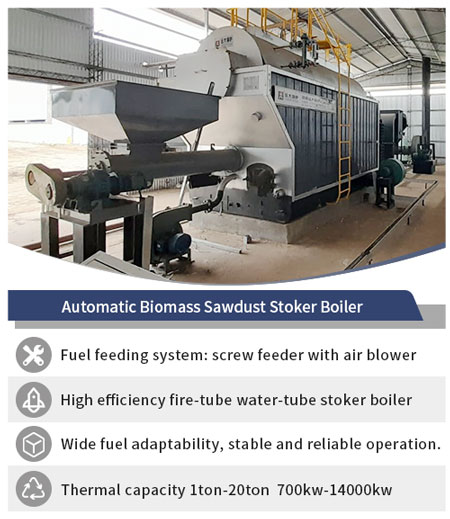

Biomass Sawdust Stoker Boiler

DZH series horizontal water-tube fire-tube boiler, specially designed for coal and biomass fuels. It adopts a travelling grate stoker system, ensuring stable combustion, and reliable steam output.

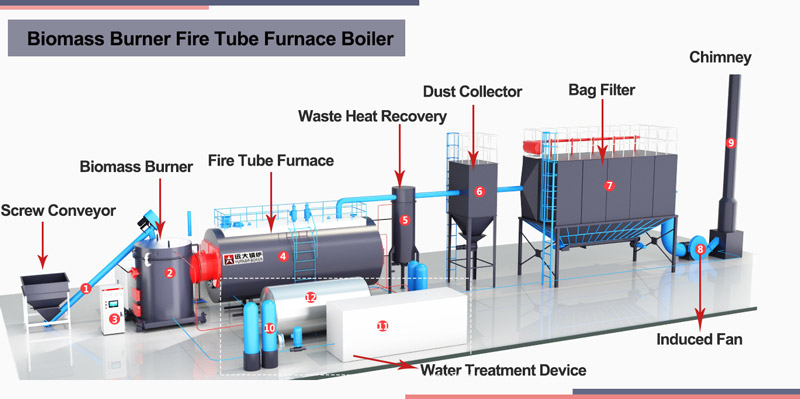

Combustion & Fuel Feeding System

The boiler is equipped with a screw feeder combined with an air blower, delivering sawdust continuously and evenly onto the travelling grate.

Combustion & Fuel Feeding System

1. Travelling Grate Stoker Technology

Proven grate design provides stable operation, uniform fuel distribution, and reliable ash discharge, suitable for long-term industrial operation.

2. Wide Fuel Adaptability, Stable Operation

Capable of handling fuel quality fluctuations while maintaining steady steam generation and safe boiler performance.

3. High Reliability & Easy Maintenance

Simple mechanical structure, convenient inspection access, and mature auxiliary systems ensure low maintenance cost and long service life.

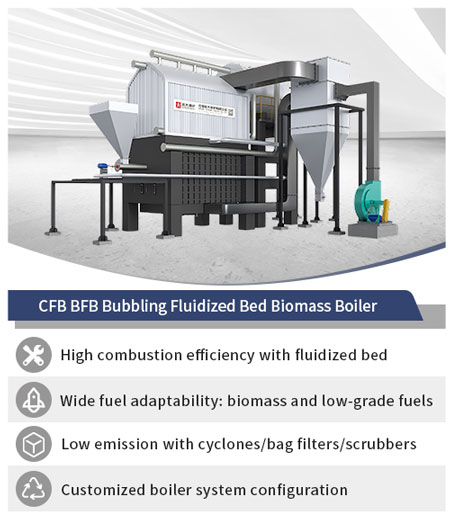

Related Bubbling/Fluidied Bed Boiler

Boiler Capacity 4ton-100ton

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

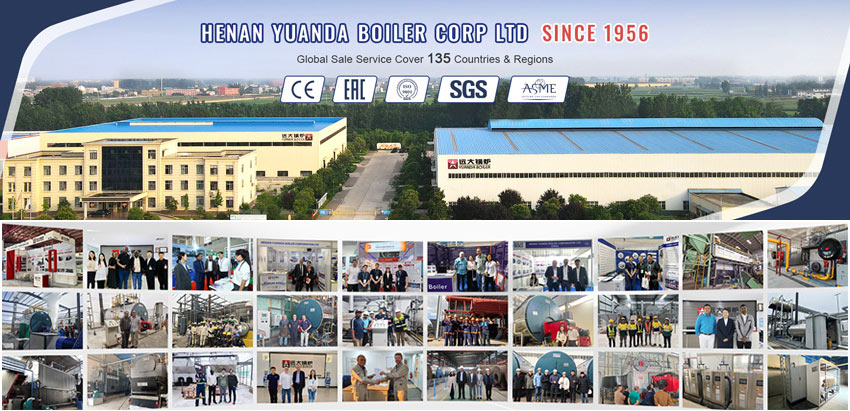

About us Yuanda Boiler

1. All products Certified With ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

2. Our company established since 1956, over 70 years manufactureing experiences, 15 Years export experience.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 135 countries all over the world, trustable quality & services for lifespan.

| Boiler model | Rated capacity |

Rating pressure |

Feed temperature |

Steam temperature |

Pellet consumption | Thermal efficiency |

Weight | Dimensions |

|---|---|---|---|---|---|---|---|---|

| t/h | MPa | ℃ | ℃ | Kg/h |

% |

Ton | mm | |

| WNS1-1.0-T | 1 | 1 | 20 | 184 | 150 | 91 | 4.3 | 3561×1690×1910 |

| WNS 2-1.25- T | 2 | 1.25 | 20 | 194 | 300 | 92 | 7.2 | 4111×1950×2199 |

| WNS3-1.25-T | 3 | 1.25 | 20 | 194 | 450 | 92.1 | 8 | 4330×2248×2564 |

| WNS4-1.25- T | 4 | 1.25 | 20 | 194 | 600 | 93 | 9.6 | 4732×2150×2448 |

| WNS5-1.25- T | 5 | 1.25 | 20 | 194 | 750 | 93 | 12.5 | 5970×2360×2796 |

English

English

.png)