- Home

- Products

Oil Gas Boiler

Oil Gas Boiler

- WNS Series Liquid Fuel Oil Diese...

- Vertical Gas Lpg Diesel Hot Wate...

- SZS Series Double Drums Diesel G...

- Industrial Portable Skid-mounted...

- Waste Heat Recovery Steam Genera...

- Liquid Fuel Oil Bunker Diesel Oi...

- Liquid Fuel Waste Oil Bunker Oil...

- Gas Burner Boiler Natural Gas Lp...

- Oil Lpg Gas Hot Water Boiler

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- Small Solid Fuel Coal Heating Bo...

- SHX/DHX Series Bubbling Fluidize...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Industrial Solid Fuel Water Heat...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg Diesel Fired Thermal Oil...

- Solid Fuel Coal Wood Biomass The...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- YLW Series Horizontal Coal Therm...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Seires Vertical Wood Biomass...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

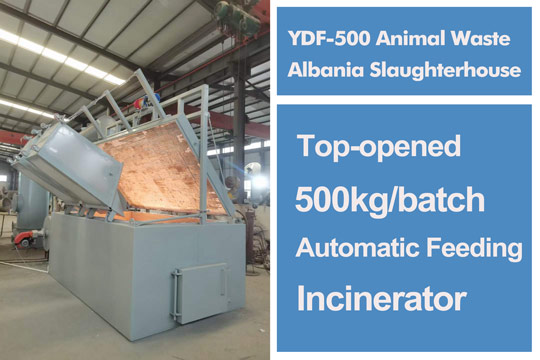

Aquaculture Waste Incineration Machine Incinerator

- Incinerator For:Aquacultural range of waste

- Power:Gas, Diesel, Waste Oil, Lpg, Heavy Oil

- Volume In:10kg-1000kg

- Working:Semi-Automatic

- Manufacture Standard:ISO CE

Aquaculture Fish Waste Incinerators

The Aquacultural range of waste incinerators, safely disposing of all forms of high moisture waste. Offer perfect solution for Fish Farms worldwide.

Please choose suitable size, contact us for price details.

Customized Incinerators

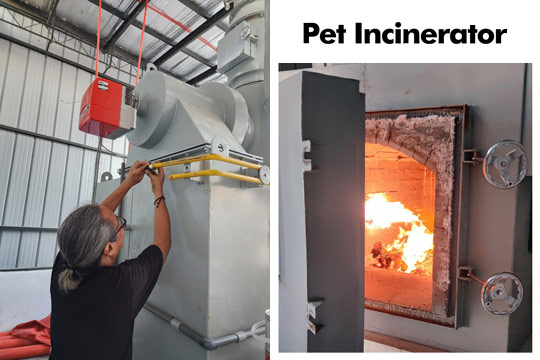

Advantages & Features

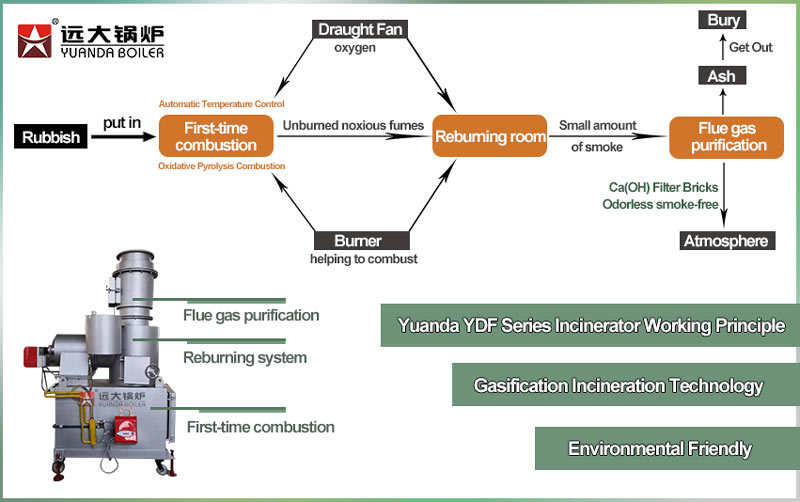

1. Smokeless and Odorless, No Blank Smoke

High-temperature pyrolysis gasification technology+mixed incineration+burnout treatment.

Single/double/multi-stage flue gas treatment.

Enclosed burning, avoid secondary pollution.

2. High Temperature Pyrolysis Process

Double chamber for incineration.

The chamber temperature up to 1300°C, retention 2 seconds.

3. Low Consump Cost

With first-class Itlay Baltur burner, ensure good qualtiy.

Primary combustion chamber automatically starts and stops, effectively utilizing high-temperature flue gas, save fuel.

4. Safe 100%, Good Quality

Use ceramic fiber sealing tape rather than asbestos material. And high-strength refractory materials.

Security protection: auto ignition, auto control and temperature monitoring, automatic power cut off.

5. Easy to Install and Operate

Pre-assembled and well-debugged in our factory.

Simple to install the incinerator by Installation Steps.

Projects Site

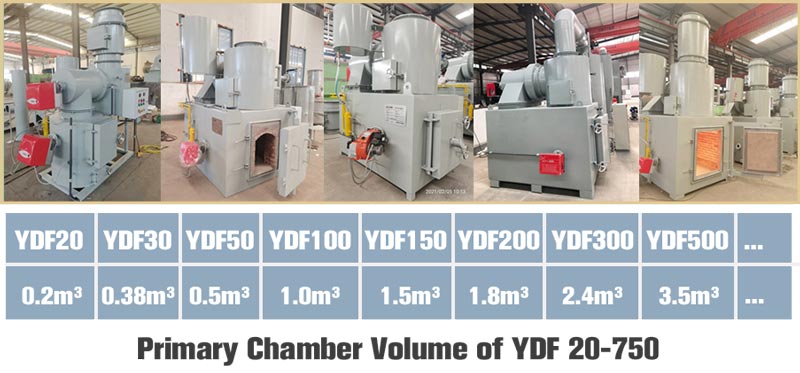

Yuanda YDF Incinerators Equipment

Incinerator with filtration system

| Models | YDF-20 | YDF-30 | YDF-50 | YDF-100 | YDF-150 | YDF-300 | YDF-500 | |

|---|---|---|---|---|---|---|---|---|

| Processing Capacity (kg/batch) | 10-20 | 20-30 | 30-50 | 50-100 | 100-150 | 200-300 | 300-500 | |

| Working Hours Per Batch Cycle* (min) | 90-120 | |||||||

| Primary Chamber Volume (m3) | 0.2 | 0.38 | 0.5 | 1 | 1.5 | 2.4 | 3.5 | |

| Waste Feeding Gate Size (mm) | 380 x 480 | 480 x 600 | 620 x 800 | 700 x 900 | 760 x 960 | 900 x 1100 | 1080 x 1280 | |

| Temperature (℃) | Primary Chamber | 900 | ||||||

| Second Chamber | 1300 | |||||||

| Smoke Residence Time (s) | > 2 sec in second chamber | |||||||

| Applicable Waste Type | Hazard Medical Waste/Consumables, Plastic, Paper, Domestic Waste, Animal Corpse, Electronic Component | |||||||

| Primary Burner - Baltur Italy | BTL-6, 0.11kw | BTL-6, 0.11kw | BTL-10, 0.11kw | BTL-10, 0.11kw | BTL-10, 0.11kw | BTL-10, 0.11kw | BTL-14, 0.18kw | |

| Second Burner - Baltur Italy | BTL-10, 0.11kw | BTL-14, 0.18kw | BTL-14, 0.18kw | BTL-20, 0.18kw | BTL-20, 0.18kw | BTL-26, 0.25kw | BTL-35, 0.37kw | |

| Total Diesel** Consumption (litre/h) | 11-18 | 11-18 | 14-23 | 16-35 | 16-35 | 20-40 | 38-57 | |

| FD Fan Power (kw) | 0.37 | 0.37 | 0.55 | 0.75 | 0.75 | 0.75 | 0.75+0.75 | |

| Applicable Voltage | 380V 3Phase / 220V 1Phase | |||||||

| Outer Dimensions (m) | 1.6 x 1.3 x 2.65 | 1.45 x 0.9 x 2.6 | 1.8 x 1.2 x 3 | 1.86 x 1.4 x 3.2 | 2.1 x 1.5 x 3.5 | 2.25 x 1.6 x 3.8 | 3.0 x 2.0 x 4.8 | |

| Chimney Dimensions (mm) | φ280 x 6000 | φ280 x 6000 | φ300 x 9000 | φ330 x 9000 | φ380 x 9000 | φ400 x 9000 | φ460 x 9000 | |

| Weight (kg) | 2000 | 3000 | 5000 | 6800 | 8000 | 9600 | 15000 | |

| Manufacturing Standard | GB 18484-2020 (equals to EPA or EU standards) | |||||||

English

English

.png)