- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- DHL Water Tube Corner Tube Coal ...

- SHX Circulating Fluidized Bed Co...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Small Solid Fuel Coal Heating Bo...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg HFO Diesel Fired Thermal...

- Solid Fuel Coal Wood Biomass Fir...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- Horizontal Coal Biomass Thermal ...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Vertical Coal Wood Biomass T...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

Steam Boiler For Commercial Kitchen & Food Factory

- Our Products :Steam Boiler, Steam Generator, Hot Water Boiler, Thermal Oil Boiler, Thermic Fluid Heater, Hot Air Furnace

- Capacity:50kg-50000kg 35kw-35000kw

- Fuel:Gas, Lpg, Diesel, Electric, Wood, Coal, Biomass

- Heat Temp:100°C-300°C

- Manufacture Standard:GB, ISO, SGS, DOSH, CE, ASME

Kitchen Steam Boiler

Boilers are used to generate steam, which is then employed for cooking, heating food, reheating, sterilization, and, in some cases, cleaning and sanitation purposes.

How To Choose Steam Boiler

1. Size and Capacity: The boiler should be appropriately sized for the kitchen's needs.

2. Fuel Type: Kitchen steam boilers can be powered by electricity, natural gas, propane, or even biomass.

3. Efficiency: High-efficiency boilers convert more fuel into steam, reducing operating costs over time.

4. Safety and Sanitation: The boiler should meet all local and national safety standards. For food service applications, ensuring the steam is clean and free of contaminants is crucial, so food-grade boilers designed specifically for culinary use are recommended.

5. Maintenance and Durability: Choose a boiler known for reliability and durability. Regular maintenance is vital for safety, efficiency, and longevity, so consider the availability of spare parts and service.

Boiler For Commercial Kitchen

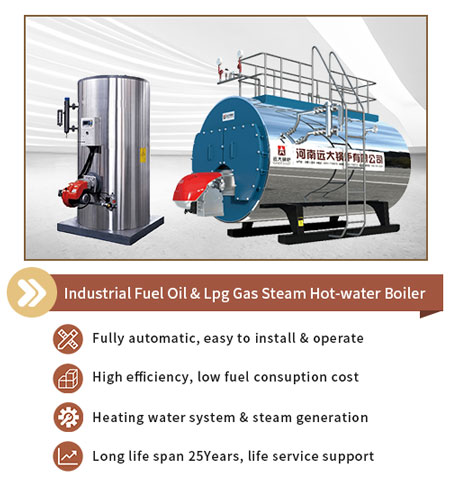

||| Most Popular: Industrial Fuel Oil Diesel Lpg Gas Boiler |||

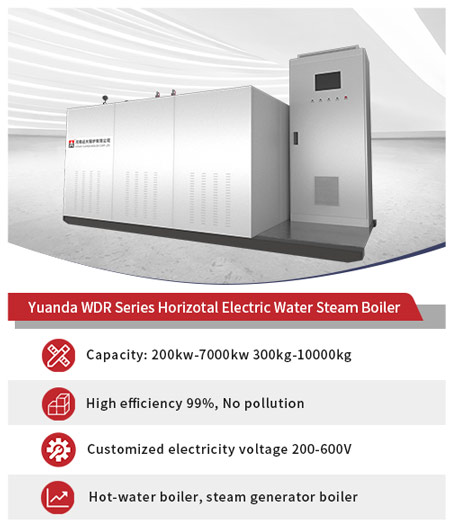

||| New Trend: Electrical Hot Water Steam Generator Boiler |||

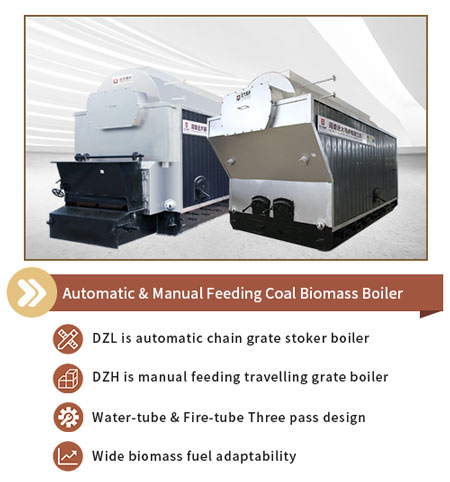

||| Economic Small Wood Boiler Biomass Boiler Coal Boiler |||

Catalogue All Products

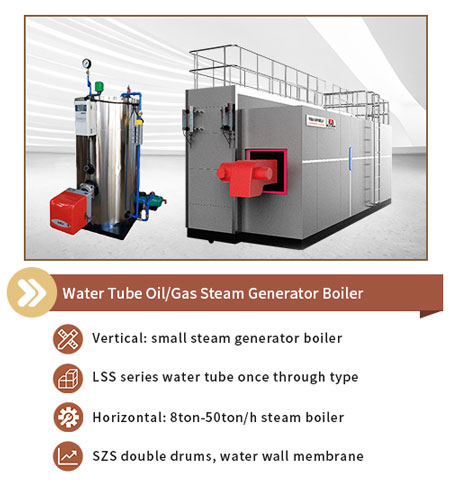

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

About us Yuanda Boiler

1. Our company established since 1956, over 65 years manufactureing experiences, 15 Years export experience.

2. Qualified by ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 132 countries all over the world, trustable quality & services for lifespan.

| Lpg/Gas/Diesel Fired Steam Generator Boiler | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | LSS0.05-0.7-Y.Q | LSS0.1-0.7-Y.Q | LSS0.125-0.7-Y.Q | LSS0.2-0.7-Y.Q | LSS0.25-0.7-Y.Q | LSS0.3-0.7-Y.Q | LSS0.5-0.7-Y.Q | ||

| Project | Unit | ||||||||

| Rated evaporation | Kg/h | 50 | 100 | 125 | 200 | 250 | 300 | 500 | |

| Rated working pressure | MPa | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | |

| Staturated steam temperature | ℃ | 170 | 170 | 170 | 170 | 170 | 170 | 170 | |

| Fuel consumption | Light diesel oil | kg/h | 3.5 | 6.8 | 8.5 | 14 | 16 | 20 | 33 |

| Natural gas | Nm³/h | 3.5 | 7.3 | 9.2 | 14.5 | 19 | 22 | 36.5 | |

| LPG | Nm³/h | 3.3 | 5.7 | 7.2 | 11.4 | 7.5 | 17.3 | 28.7 | |

| City gas | Nm³/h | 8.5 | 18 | 22.5 | 34 | 43 | 52 | 88 | |

| Water capacity | L | 29 | 49.3 | 49.3 | 49.5 | 49.5 | 49.5 | 49.6 | |

| a Main steam valve diameter | DN | 15 | 25 | 25 | 32 | 32 | 32 | 50 | |

| b Safety valve diameter | DN | 20 | 20 | 20 | 25 | 25 | 25 | 40 | |

| c Inlet diamater | DN | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

| d Blowoff Valve diameter | DN | 20 | 20 | 20 | 25 | 25 | 25 | 25 | |

| Chimney diameter | DN | 80 | 125 | 125 | 150 | 150 | 150 | 250 | |

| Overall size | L | mm | 820 | 880 | 900 | 1400 | 1500 | 1500 | 1800 |

| W | mm | 890 | 1100 | 1150 | 1000 | 1100 | 1200 | 1300 | |

| H | mm | 1600 | 1800 | 1900 | 1000 | 2200 | 2200 | 2350 | |

| Weight | kg | 180 | 220 | 240 | 850 | 1150 | 1200 | 1680 | |

English

English

.png)