- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- DHL Water Tube Corner Tube Coal ...

- SHX Circulating Fluidized Bed Co...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Small Solid Fuel Coal Heating Bo...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg HFO Diesel Fired Thermal...

- Solid Fuel Coal Wood Biomass Fir...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- Horizontal Coal Biomass Thermal ...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Vertical Coal Wood Biomass T...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

Heat Transfer Fluid Oil

- Name:Thermal Conduction Oil

- Keywords:Heat Transfer Oil

- Max Working Temp.:280°C, 300°C, 310°C, 320°C, 330°C, 340°C...400°C

Heat Transfer Fluid Oil

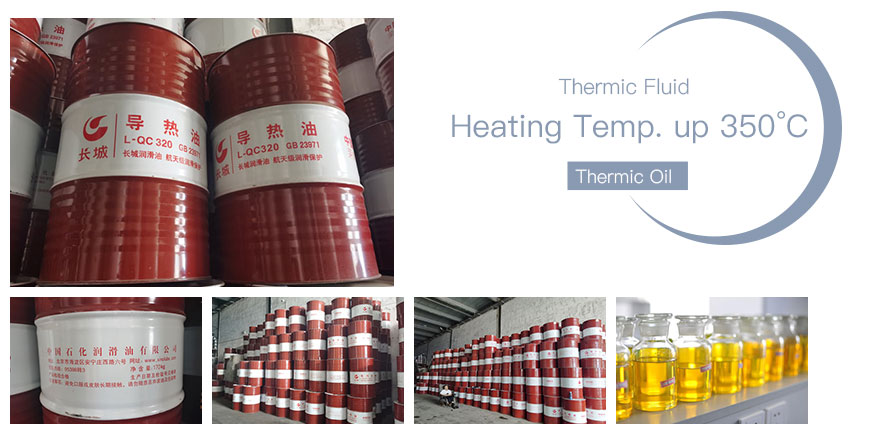

Heat Transfer Oil is a highly refined and stable paraffinic oil designed to be used as a heat transfer medium. Also named Synthetic Heat Transfer Fluid.

Max Working Temperature:

Range 280°C, 300°C, 310°C, 320°C, 330°C, 340°C...400°C

Features:

1. Low viscosity for efficient heat transfer.

2. Good thermal and oxidation stability for long service life.

3. High thermal conductivity for quick rates of heat transfer.

4. Low pour point to avoid cold start difficulties.

5. Non-corrosive to steel, stainless steel or aluminum heat transfer systems.

6. Economical – long life oil.

Benefits:

1. High Temperature Life: Excellent stability extends high temperature operating times

2. Low Volatility: Volatility control enables operation in closed high temperature, low pressure systems.

3. Conductivity: Good conductivity provides rapid cooling and heating operations.

4. Good Pumpability: Good pumpability at start-up provides low energy requirement.

|

Item |

Quality Index |

Testing Method |

|||||||

|

|

L-QB |

L-QC |

L-QD |

|

|||||

|

|

280 |

300 |

310 |

320 |

330 |

340 |

350 |

XXX |

|

|

Max working temperature |

280 |

300 |

310 |

320 |

330 |

340 |

350 |

XXX |

GB/T 23800 |

|

Appearance |

Clear and transparent, No suspension |

Visual inspection |

|||||||

|

Spontaneous ignition point |

Max working temperature |

SH/T 0642 |

|||||||

English

English

.png)

.jpg)