- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- Small Solid Fuel Coal Heating Bo...

- SHX/DHX Series Bubbling Fluidize...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Industrial Solid Fuel Water Heat...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg Diesel Fired Thermal Oil...

- Solid Fuel Coal Wood Biomass The...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- YLW Series Horizontal Coal Therm...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Seires Vertical Wood Biomass...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

How To Choose Steam Boiler For Paper Mill

01 / Dec

Industrial Boilers for Paper Mills: Steam Demand, Production Output, and Selection Guide

The paper manufacturing industry is one of the world’s most energy-intensive sectors. Steam plays a central role in both pulp processing and paper drying, choosing a right steam boiler directly affects production stability, paper quality, energy efficiency, and overall operating costs.

1. Steam Demand in Paper Production

Steam is consumed throughout the papermaking process, mainly in:

Pulping (heating, cooking, washing)

Paper machine drying section

Steam showers, preheaters, and hood systems

Plant heating and thermodynamic processes

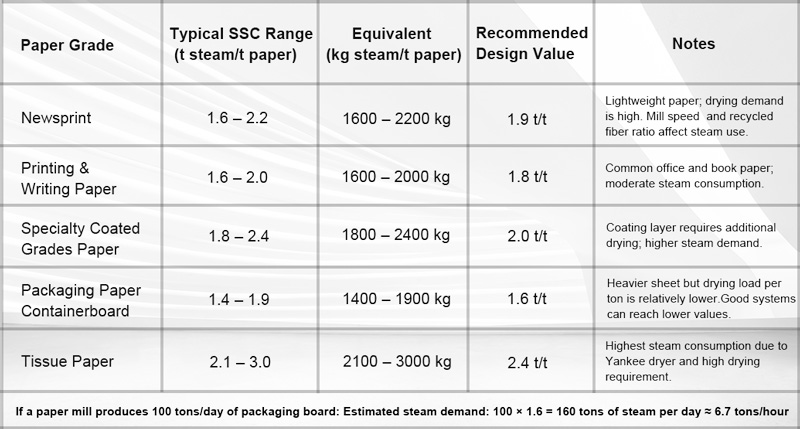

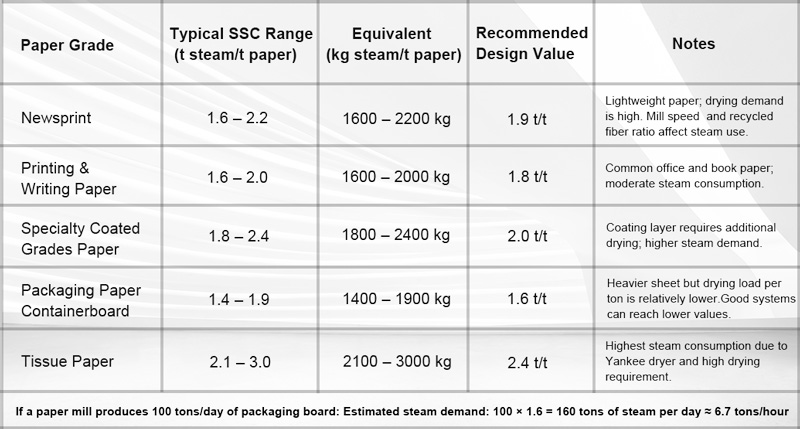

Typical Steam Consumption by Paper Grade (SSC Values) — Steam Required to Produce 1 Ton of Paper

2. Boiler Requirements in Paper Mills

1) High thermal efficiency, reduce fuel cost, especially for large-scale mills.

2) Steady steam output & pressure stability, for paper machine drying sections.

3) Ability to run long hours, paper mills often operate 24/7, so reliability is crucial.

4) Flexible fuel options, commonly use: biomass, wood, coal, oil, gas.

5) Good automation & safety control, stable steam temperature and moisture consistency.

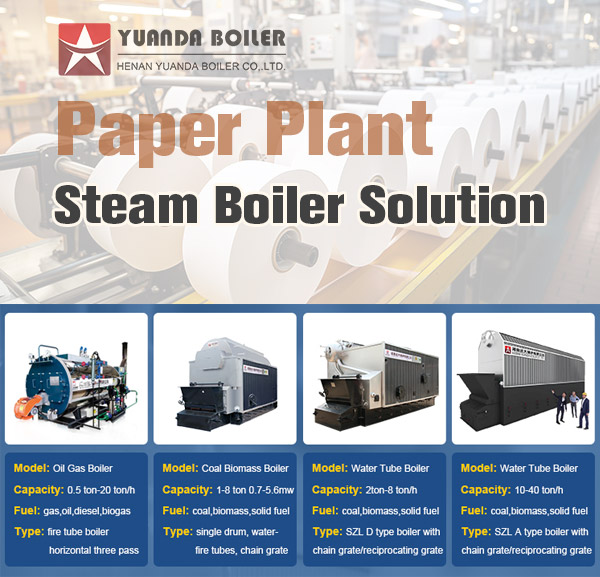

3. Various of Steam Boilers

1) Biomass Steam Boilers: Low operating cost, Renewable and environmentally friendly, Suitable for 4–50 ton/hr steam demand

2) Coal-Fired Steam Boilers: High efficiency, strong output, Good for large-scale mills (10–75 ton/hr)

3) Gas or Oil-Fired Boilers: High automation, Quick start-up, Suitable for 1–20 ton/hr steam demand

4. Yuanda Boiler Services

Yuanda Boiler offers complete boiler system solutions tailored to paper industry applications.

1) Professional Recommendation

Our engineering team analyzes your paper mill’s production data — including daily paper output, steam pressure, and operating schedule — to recommend the most suitable boiler type and capacity.

We provide options for biomass, coal, gas, or multi-fuel boilers depending on your local fuel availability.

2) Fuel Cost and Operation Analysis

We calculate the fuel consumption and cost per ton of steam, helping you compare different energy options and select the most economical solution for long-term operation.

3) Complete Boiler System Design

Yuanda provides detailed boiler system diagrams, including: Steam pipeline layout, Water treatment system, Chimney design, Air and flue gas systems, Condensate recovery solutions

4) Boiler House Design & Construction Guidance

Our technical team can offer guidance on boiler room layout, foundation, ventilation, and auxiliary equipment installation, ensuring safety and space efficiency in your plant.

5) On-Site Engineer Support

We provide on-site installation supervision, commissioning, and operator training, guaranteeing that your boiler runs safely and efficiently from day one.

6) Trustable & Professional

With decades of manufacturing experience and thousands of project references, Yuanda Boiler helps paper mills achieve higher productivity, lower fuel costs, and sustainable operation.

We’re ready to design the perfect boiler system for your paper production line — from initial consultation to full project delivery.

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible

Copyright © Henan Yuanda Boiler Corporation Ltd. All Rights Reserved Site Index

Privacy policy

English

English

.png)