- Home

- Products

Coal Boiler

Coal Boiler

- Industrial Coal Fired Boiler Sol...

- Vertical Coal Boiler Small Solid...

- SZL Series Water Tube Boiler Dou...

- DZH Sereis Coal Charcoal Briquet...

- DHL Water Tube Corner Tube Coal ...

- SHX Circulating Fluidized Bed Co...

- Briquette Coal Biomass Wood Hot ...

- Charcoal Wood Coal Hot Water Ste...

- Small Solid Fuel Coal Heating Bo...

Thermal Oil Boiler

Thermal Oil Boiler

- Gas Lpg HFO Diesel Fired Thermal...

- Solid Fuel Coal Wood Biomass Fir...

- Electric Thermal Oil Heater Boil...

- YQL Vertical Diesel Gas Fired Th...

- Horizontal Coal Biomass Thermal ...

- Edible Oil Heater For Fryer

- Waste Heat Recovery Thermal Oil ...

- YGL Vertical Coal Wood Biomass T...

- Small Gas Thermal Oil Heater

- About us

- Services

- Case

- News

- Contact us

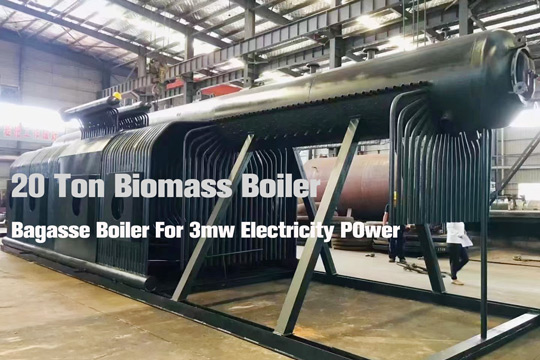

Steam Boiler For Electricity Generation With Turbine Generator

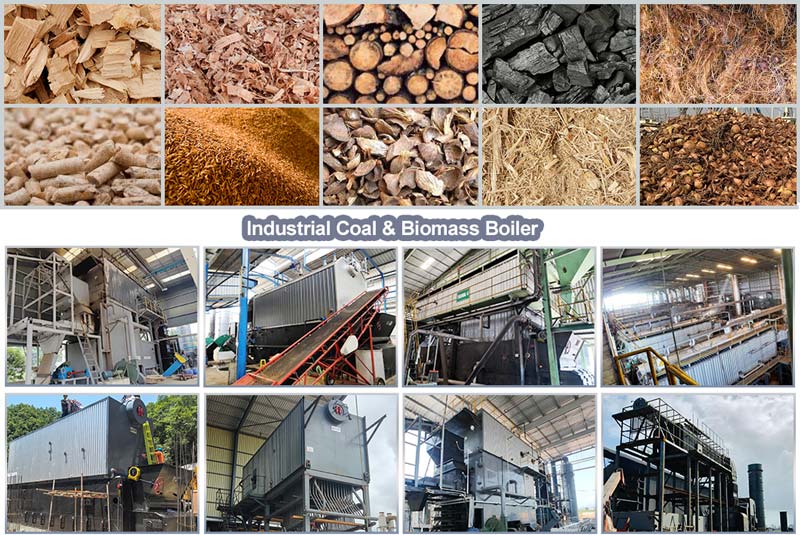

- Fuel:Biomass, coal, wood, sawdust, bagasse, ricehusk, palm kernel shells, palm fibre, agro waste

- Capactiy:1ton-120ton

- Steam pressure:1.0mpa-4.5mpa

- Power generation:100kw-10,000kw

- Manufacture Standard:GB, ISO, CE, ASME, DOSH, EAC

Coal Biomass Steam Boiler Power Generation

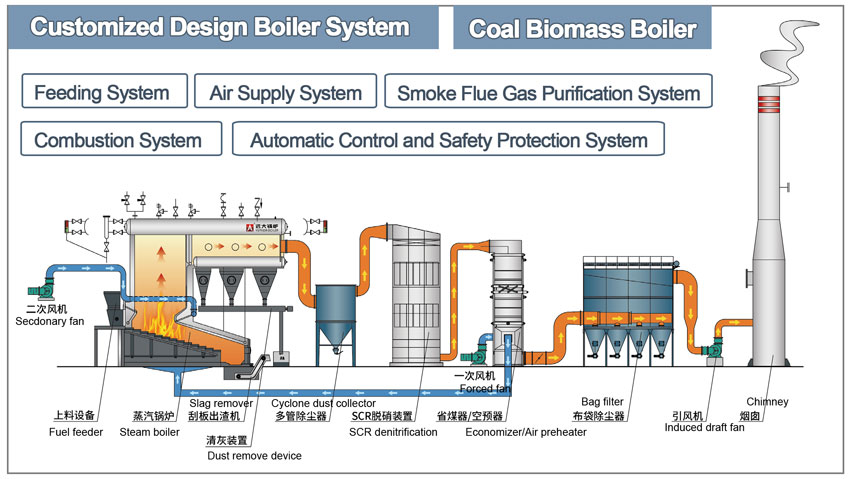

Industrial Steam Boiler & Steam Turbine Generator For Electricity Power Generation

||| Production Heat & Power Coal Wood Biomass Boiler |||

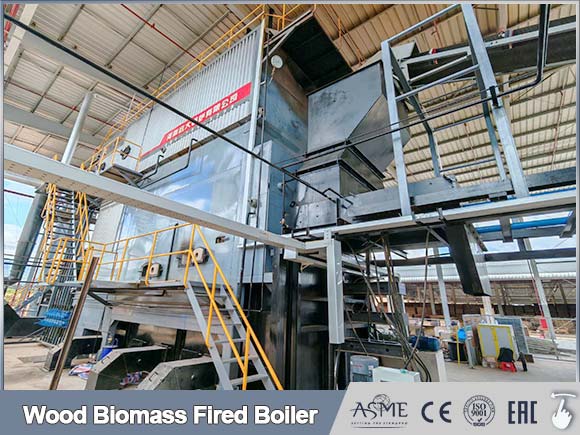

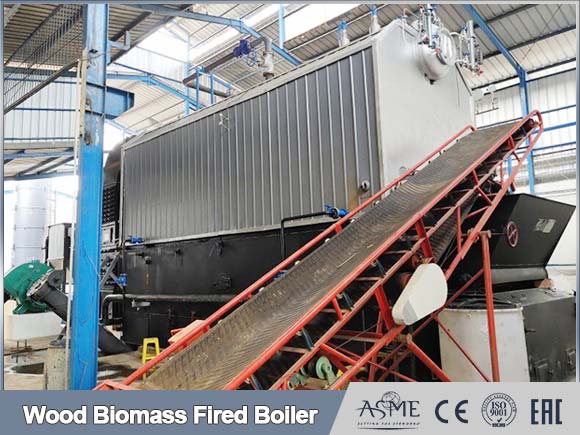

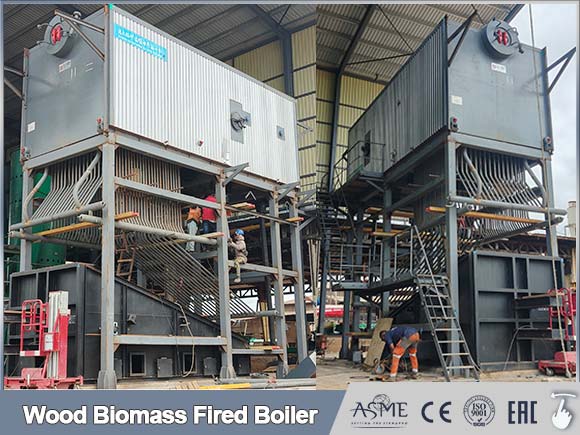

SZL / SZW series boiler is a double-drum water tube boiler featuring an offset furnace structure, commonly known as “D-type” or “A-type” layout. It is designed for efficient and stable combustion of coal, biomass and other solid fuels, and is widely used in industrial steam supply and power generation applications.

With advanced combustion technology and optimized heat transfer design, the boiler offers high efficiency, reliable operation and environmental performance, making it an ideal solution for medium and large-scale industrial plants.

Water Tube Boiler Features

High Efficiency & Energy Saving

1. Double-drum water tube structure for efficient heat transfer

2. Large furnace volume suitable for biomass and mixed fuels

3. Reduced fuel consumption and lower operating cost

Stable & Reliable Operation

1. Mature and proven SZL / SZW boiler design

2. Suitable for continuous industrial operation

3. Strong adaptability to fuel quality variation

Environmentally Friendly

1. Low emission design with dust collection system

2. Meets environmental protection requirements

3. Supports renewable biomass utilization

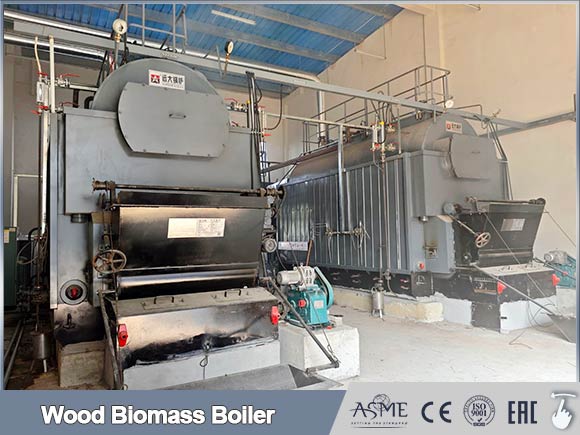

Flexible Design & Customization

1. Steam boiler or hot water boiler available

2. Capacity, pressure and fuel system customized

3. Optional economizer, air preheater and automation system

Steam Turbine Generator

Steam turbine generator is the primary power conversion component of the power plant. The function of the steam turbine generator is to convert the thermal energy of the steam from the steam generator to electrical energy.

Based on steam turbine parameter, we can get boiler details including steam temperture, steam pressure, steam flow.

Related Coal Biomass Boiler

DHL DZW series corner tube boiler, coal or biomass fired steam boiler 15ton-120ton.

Circulating Fluid Bed Coal Biomass Boiler 4ton-120ton.

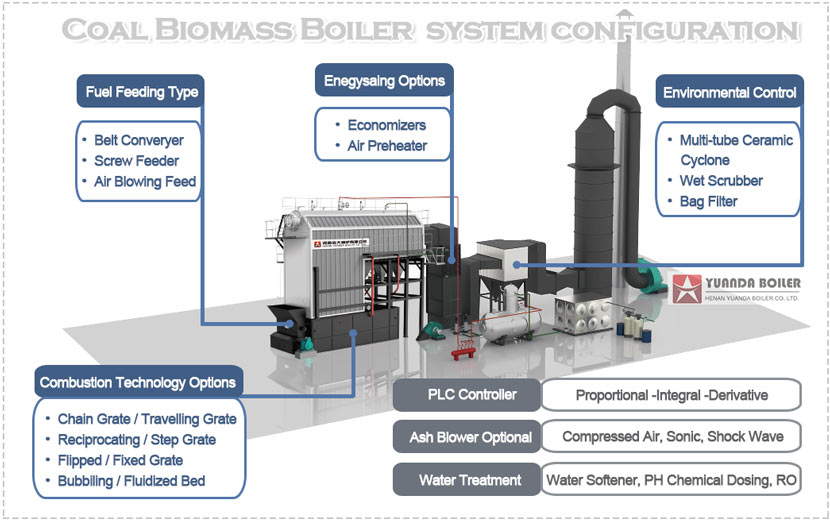

Customized As Rerequired

Each power generation project has different requirements in fuel type, steam parameters, plant layout and environmental standards.

Tell us your fuel type, steam parameters and power output, and our engineers will provide a professional technical proposal tailored to your project.

1. Steam Parameters

Steam capacity, pressure and temperature customized

Superheated steam design for turbine power generation

2. Fuel & Combustion System

Coal, biomass or mixed fuel firing

Grate firing, suspension firing or CFB design

Adapted for high-moisture or low-calorific fuels

3. Integrated boiler island design

Energy Efficiency & Heat Recovery

Economizer, air preheater, superheater

Improved overall thermal efficiency

4. Environmental Protection System

Multi-stage dust removal (cyclone, bag filter, ESP)

Low emission design compliant with local regulations

5. Automation & Control

PLC / DCS control system

Remote monitoring and automatic operation

Complete Power Plant Solution

6. Beyond the boiler itself, we can also supply:

Steam turbine and generator matching

Auxiliary systems and piping layout

Installation guidance and commissioning support

Catalogue All Products

1. Gas boiler, Lpg boiler, Diesel boiler, Heavy oil boiler, Dual fuel boiler, Exhaust gas waste heat recovery boiler

2. Coal boiler, Charcoal boiler, Wood boiler, Biomass boiler, Pellet boiler, Ricehusk boiler, Palm shells boiler

3. Electric boiler, Electric steam generator, Electric hot water boiler,

4. Thermal Oil Heater Boiler, Thermic Fluid Heater, Hot Oil Boiler. (Powered by gas, diesel, electric, coal, wood biomass)

5. Steam Boiler, Hot Water Boiler, Steam Generator Boiler, Combined Heat and Power Boiler, Superheated Steam Boiler

About us Yuanda Boiler

1. Our company established since 1956, over 70 years manufactureing experiences, 15 Years export experience.

2. Qualified by ASME, CE, ISO, EAC, DOSH, TUV, BUV, Ensuring High Quality and Compliance with International Standards.

3. Global service team for boiler solution, boiler design, order contract, boiler delivery, boiler install and commissioning.

4. Until now, our products have been exported to 135 countries all over the world, trustable quality & services for lifespan.

| SZL Series Biomass Steam Boiler Technical Parameter Table | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Rated capacity(t/h) | Rated pressure (Mpa) | Rated steam temperature(℃) | feed temperature(℃) | Thermal efficiency(%) | Boiler water volume(m³) | Exhaust temperation(℃) | Fuel comsumption(Kg/h) | max transportation weigh(t) |

| SZL2 | 2 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >83.13 | 6.76 | 130.7 | 385.8 | 22 |

| SZL4 | 4 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >84.23 | 5.1 | 142 | 807 | 29 |

| SZL6 | 6 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >84.81 | 8.4 | 142 | 1209 | 34 |

| SZL8 | 8 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >85.02 | 9.4 | 149.1 | 1563.9 | 40.5 |

| SZL10 | 10 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.2 | 8.35 | 152.7 | 2149.3 | 24 |

| SZL12 | 12 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.56 | 12.8 | 148.7 | 2399.7 | 37 |

| SZL15 | 15 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.29 | 15.2 | 149.8 | 2568.4 | 24.7 |

| SZL20 | 20 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.8 | 15.5 | 147.4 | 4266.9 | 26 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

English

English

.png)